Aluminum Die Casting Defects and Solution

The below are main defects of Aluminum die casting parts and the relative solutions for them.

I. Flow marks and patterns

Appearance inspection: There are stripes on the surface of castings which are consistent with the direction of liquid metal flow. There are obvious undirected stripes which are different from the color of metal matrix, and there is no development trend.

1. The causes of flow marks are as follows:

(1) The die temperature is too low.

(2) Poor design of runner and poor position of inner gate.

(3) The material temperature is too low.

(4) Low filling speed and short filling time.

(5) Irrational gating system.

(6) Poor exhaust.

(7) spray is unreasonable.

2. The reason for the pattern is that there are too many coatings sprayed in the cavity or the quality of the coatings is poor. The methods to solve and prevent the pattern are as follows:

(1) Adjusting the section area or position of the inner runner.

(2) Increasing die temperature.

(3) Adjusting the speed and pressure of the inner runner.

(4) Proper selection of coatings and adjustment of dosage.

2. reticulate hairy wings (tortoise cracks)

Appearance inspection: The surface of die castings has the marks of protrusion or depression like reticular hairline, which expands and extends with the increase of the number of die castings.

The reasons are as follows:

(1) There are cracks on the surface of die casting die cavity.

(2) Non-uniform preheating of die casting die.

The solutions and preventive measures are as follows:

(1) Die casting die should be annealed regularly or after a certain number of times of die casting to eliminate the stress in the cavity.

(2) If there is a tortoise crack on the surface of the cavity, the forming surface should be polished to remove the crack layer.

(3) The preheating of the die should be uniform.

3.Cold separation

Appearance inspection: The surface of die castings has obvious, irregular, subsidence linear pattern (penetration and non-penetration) with small and narrow shape, sometimes smooth edge of the junction, and the possibility of disconnection under the action of external forces.

The reasons are as follows:

(1) The two metal streams butt each other, but they are not fully fused and there is no inclusion between them, and the bonding force between the two metal streams is very weak; (2) the pouring temperature or the temperature of die casting die is low;

(3) Incorrect runner position or long flow path;

(4) Low filling speed.

The solutions and preventive measures are as follows:

(1) Increasing pouring temperature appropriately;

(2) Increase the injection ratio, shorten the filling time and increase the injection speed.

(3) Improve exhaust and filling conditions.

4. Shrinkage (indentation)

Appearance Inspection: Smooth dents (like discs) are found on most of the thick surface of die castings.

The reasons are as follows:

(1) Caused by contraction

1.1 The design of die castings is improper and the wall thickness difference is too large.

1.2 improper position of runner;

1.3 The injection pressure is lower and the holding time is shorter.

1.4 The local temperature of die casting die is too high.

(2) The design of cooling system is unreasonable;

(3) Opening the mould too early;

(4) The pouring temperature is too high.

The solutions and preventive measures are as follows:

(1) The wall thickness should be uniform;

(2) The transition between thickness and thickness should be moderated.

(3) Correctly select the position of alloy liquid and increase the cross-section area of the inner runner; (4) Increase the injection pressure and prolong the holding time;

(5) Properly reduce the pouring temperature and die casting temperature;

(6) Local cooling is necessary for local high temperature.

(7) Improving spillover conditions;

5. Prints

Appearance Inspection: Traces left by the contact between the surface of the casting and the surface of the die casting model cavity or staircase marks on the surface of the casting.

The reasons are as follows:

1. Caused by ejector

(1) The end face of the top rod is worn out;

(2) The adjustment length of the ejector rod is inconsistent;

(3) The splicing part of die casting die cavity does not match well with other parts; 2) It is caused by splicing or moving part.

(1) The mosaic part is loose;

(2) loosening or wearing of the movable part;

(3) The side wall surface of the castings is formed by the inserts with the moving and fixed dies interpenetrating each other.

The solutions and preventive measures are as follows:

(1) The length of the ejector rod should be adjusted to an appropriate position;

(2) Fastening inserts or other movable parts

(3) Eliminate the sharp angle in design and adjust the clearance properly;

(4) Improving the structure of the castings, eliminating the insertion of the die-casting die and improving the structure of the die-casting die;

6. Adhesive Traces

Appearance Inspection: Small sheet and metal or non-metal are welded with the metal matrix. Under the action of external force, small sheet is peeled off. Some of the surface of the peeled castings is bright and some are dark gray.

The reasons are as follows:

(1) There are metal or non-metal residues on the surface of die-casting model cavity; (2) impurities are added to the surface of die-casting model cavity before pouring.

The solutions and preventive measures are as follows:

(1) Before die casting, the cavity chamber and pouring system should be cleaned up, and metal or non-metal adhesives should be removed; (2) the pouring alloys should also be cleaned up.

(3) Choose suitable coatings, and the coatings should be uniform.

7. Layering (skin and peeling)

Appearance inspection or damage inspection: There are obvious layers of metal in the part of the casting.

The reasons are as follows:

(1) When the rigidity of the die is not enough, the die will flutter during filling process; (2) the punch will crawl during pressing process.

(3) Improper design of runner system.

The solutions and preventive measures are as follows:

(1) Strengthen the rigidity of the die and fasten the die parts to make them stable; (2) Adjust the fit between the injection punch and the chamber to eliminate the creeping phenomenon; (3) Design the inner runner reasonably.

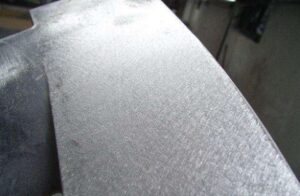

8. Friction Ablation

Appearance inspection: Rough surface is produced on the surface of die castings in some positions.

The reasons are as follows:

(1) improper position, direction and shape of the inner runner caused by die casting mold (die); (2) the cooling of the parts where the liquid metal scours intensely at the inner runner caused by casting conditions is insufficient.

The solutions and preventive measures are as follows:

(1) Improving the improper position and direction of the inner runner; (2) Improving the cooling conditions, especially the parts where the liquid metal scours violently; (3) Adding paint to the ablation part;

(4) Adjust the flow rate of the alloy liquid so that it does not produce cavitation.

(5) Eliminate the alloy adhesives on the die.

9. Erosion.

Appearance inspection: There are pits or ribs in the local position of the die casting.

The reasons are as follows:

(1) improper location of inner runner;

(2) The cooling condition is not good.

The solutions and preventive measures are as follows:

(1) The thickness of the inner runner should be appropriate;

(2) Modify the position, direction and setting method of the inner runner;

(3) Cooling should be strengthened for the eroded parts.

10. Crack

Appearance inspection: The casting is put in alkaline solution and the crack is dark grey. The failure and cracking of metal matrix are linear or wavy, with narrow and long lines, and there is a trend of development under the action of external forces.

Cracks in Aluminum Alloy Castings