China Metal Castings: Your Premier Partner for Investment Casting and Surface Treatment Solutions

Introduction

China Metal Castings is a leading investment casting manufacturer with 20+ years of expertise in producing high-precision metal components for industries worldwide. Beyond our core casting capabilities, we provide comprehensive surface treatment services that enhance the durability, functionality, and aesthetics of your parts.

This guide explores what surface treatment is, why it matters, and how our advanced finishing solutions can add value to your investment castings.

What is Surface Treatment?

Surface treatment refers to the application of protective or decorative coatings onto metal components through chemical, electrochemical, or mechanical processes. These treatments serve multiple critical purposes:

✔ Corrosion Resistance – Extends part lifespan in harsh environments

✔ Wear Protection – Improves hardness and reduces friction

✔ Aesthetic Enhancement – Provides polished, colored, or textured finishes

✔ Electrical & Thermal Properties – Modifies conductivity or insulation

Did You Know? Over 80% of industrial castings undergo some form of surface treatment to meet performance standards.

Why Choose China Metal Castings for Surface Finishing?

As a one-stop investment casting and finishing provider, we offer:

✅ In-House Surface Treatment Facility – No outsourcing delays

✅ ISO 9001 & IATF 16949 Certified – Strict quality control

✅ 50+ Coating Options – From basic anti-rust oil to PVD coatings

✅ Fast Turnaround – 30% quicker than industry averages

Industries We Serve:

-

Aerospace (Anodizing, Electroless Nickel)

-

Automotive (Powder Coating, Zinc Plating)

-

Medical (Passivation, Polishing)

-

Energy (Hot-Dip Galvanizing, Thermal Spray)

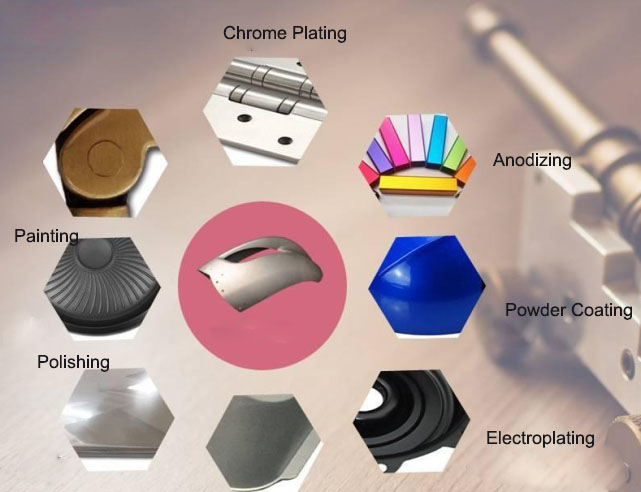

Our Comprehensive Surface Treatment Services

1. Electroplating

-

Process: Uses electric current to deposit metal ions (e.g., zinc, nickel, gold)

-

Benefits:

-

Galvanizing (5-25µm) – Salt spray resistance up to 500+ hours

-

Nickel Plating (10-50µm) – EMI shielding & wear resistance

-

Decorative Chrome (0.5-5µm) – Mirror-like finish

-

2. Hot-Dip Galvanizing

-

Temperature: 510°C molten zinc bath

-

Coating Thickness: 45-200µm

-

Best For: Structural steel, outdoor equipment

3. Electroless Nickel Plating

-

No Electricity Required – Uniform coating on complex geometries

-

Hardness: Up to 60 HRC after heat treatment

-

Applications: Hydraulic components, valves

4. Powder Coating

-

Eco-Friendly – Zero VOC emissions

-

Options:

-

Teflon-Embedded – Non-stick surfaces

-

Conductive Coatings – For electronic housings

-

5. Anodizing (Aluminum & Titanium)

-

Type II (Decorative): 5-25µm, multiple color options

-

Type III (Hardcoat): 50-70µm, 60+ HRC hardness

6. Mechanical Finishing

-

Polishing: Mirror (Ra 0.05µm) or satin finishes

-

Sandblasting: Removes oxides for better paint adhesion

(Comparison Table: Which Coating is Right for You?)

| Coating Type | Best For | Thickness | Cost |

|---|---|---|---|

| Zinc Plating | Fasteners, Brackets | 5-25µm | $ |

| Powder Coating | Automotive Parts | 50-150µm | $$ |

| PVD Coating | Medical Tools | 1-5µm | $$$ |

Advanced Surface Treatment Technologies

Vacuum Plating (PVD/CVD)

-

Process: Deposits ultra-thin coatings (1-5µm) in a vacuum chamber

-

Benefits: Extreme hardness (up to 80 HRC), superior adhesion

Ion Plating

-

Applications: Aerospace components, cutting tools

-

Advantages: Excellent wear & corrosion resistance

Surface Hardening (Case Hardening, Nitriding)

-

Increases Fatigue Life by 3X

-

Common Uses: Gears, shafts, bearings

Quality Assurance & Testing

✔ Salt Spray Testing (ASTM B117) – Corrosion resistance validation

✔ Coating Thickness Measurement (XRF/Eddy Current)

✔ Adhesion Testing (ISO 2409 Cross-Cut)

Case Study: A pump manufacturer reduced corrosion failures by 90% after switching to our duplex nickel-chrome plating.

Why Partner With Us?

🔹 End-to-End Solutions – From casting to final finishing

🔹 Material Expertise – Stainless steel, aluminum, titanium, and more

🔹 Prototype to Mass Production – 1pc to 100,000+ batches

Get a Free Surface Treatment Consultation Today!