Precision Investment Casting Services – High-Quality Lost Wax Casting Manufacturer in China

Comprehensive Introduction to Investment Casting Technology

Investment casting, also known as lost wax casting, stands as one of the most precise and versatile metal-forming processes available in modern manufacturing. With origins dating back over 5,000 years to ancient civilizations, this time-tested method has evolved into a sophisticated production technique capable of creating complex, high-tolerance metal components with exceptional surface finishes and dimensional accuracy that often eliminates the need for secondary machining operations.

At ChinaMetalCastings, we have established ourselves as a premier investment casting manufacturer based in Ningbo, China – a globally recognized production hub for high-quality casting components. With decades of collective expertise, we specialize in delivering precision investment casting solutions to diverse industries worldwide, including aerospace, automotive, medical equipment, energy, and industrial machinery applications.

Our facility incorporates state-of-the-art equipment and stringent quality control measures to ensure every casting meets the most demanding specifications. We maintain ISO 9001:2015 certification and adhere to international quality standards, demonstrating our commitment to manufacturing excellence.

Detailed Explanation of Investment Casting Process

Fundamentals of Lost Wax Casting Technology

Investment casting is a multi-step, precision manufacturing process that produces near-net-shape metal parts with superior accuracy compared to alternative methods like sand casting, die casting, or forging. The process offers distinct advantages that make it ideal for applications requiring:

- Complex geometries with intricate details

- Exceptional dimensional accuracy

- Superior surface finishes

- Material flexibility across various alloys

- Cost-effective production from prototype to mass quantities

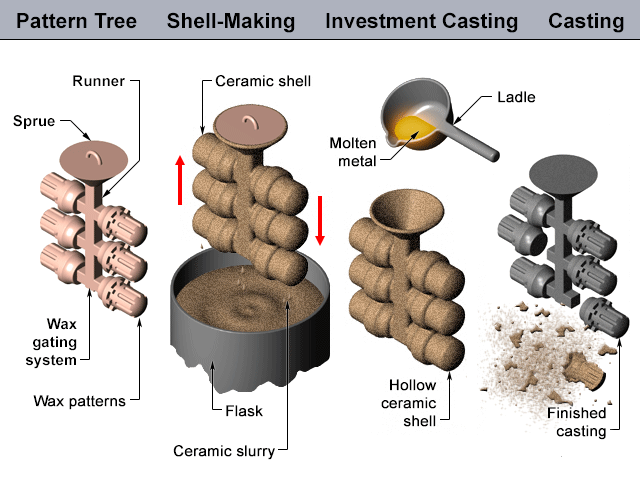

The key stages of our advanced investment casting process include:

- Advanced CAD Design & Pattern Creation – Digital modeling and precision wax pattern production

- Ceramic Shell Building – Multi-layer refractory coating application

- Dewaxing & High-Temperature Firing – Wax removal and mold preparation

- Controlled Metal Pouring – Precise molten metal introduction

- Systematic Cooling & Finishing – Controlled solidification and post-processing

This meticulous process allows for complex internal passages, tight tolerances (±0.005 in/in), and smooth surface finishes (120-150 RMS) while minimizing material waste and secondary machining requirements.

In-Depth Advantages of Our Investment Casting Services

As a trusted global investment casting supplier, we ensure every component meets the highest international quality standards while optimizing production efficiency and cost-effectiveness. Our advanced lost wax casting capabilities deliver unmatched benefits:

✅ Superior Design Capabilities

✔ Unparalleled Design Freedom – Produce intricate shapes and thin-walled sections impossible with other methods

✔ Exceptional Detail Reproduction – Achieve precise features and tight tolerances consistently

✔ Near-Net-Shape Production – Significantly reduces post-casting machining requirements

✔ Comprehensive Alloy Selection – Wide range of ferrous and non-ferrous materials available

✔ Premium Surface Quality – 120-150 RMS achievable without secondary processing

✔ Weight Optimization – Design flexibility enables lightweight yet strong components

✅ Significant Cost Benefits

✔ Minimized Material Waste – Near-net-shape casting dramatically reduces material usage

✔ Reduced Machining Costs – Less post-processing required compared to other methods

✔ Lower Tooling Investment – More economical than die casting for medium volumes

✔ Flexible Production Quantities – Cost-effective from prototypes to mass production

✔ Consolidated Assemblies – Complex multi-part assemblies cast as single components

✔ Long-Term Tool Life – Wax molds maintain dimensional stability over thousands of cycles

✅ Rigorous Quality Assurance System

We implement comprehensive quality control protocols to ensure every casting meets exacting international standards:

- Full Material Traceability – Certified mill test reports for all alloys

- Advanced Dimensional Inspection – CMM, optical comparators, and manual verification

- Non-Destructive Testing (NDT) – X-ray, dye penetrant, ultrasonic, and MPI inspection

- Mechanical Property Testing – Tensile, hardness, and impact testing capabilities

- ISO 9001:2015 Certified – Documented quality management system

- Process Validation – First article inspection and PPAP documentation

- Supplier Qualification – Approved vendor programs for critical industries

Comprehensive Material Selection for Investment Castings

We produce precision castings in an extensive range of high-performance alloys to meet diverse application requirements:

Stainless Steel Castings

Stainless steel castings offer superior corrosion resistance, strength, and durability for demanding applications. Produced through investment, sand, or precision casting, they serve industries like aerospace, medical, and chemical processing. Available in grades 304, 316, and 17-4PH, these castings provide complex geometries with excellent surface finishes. Custom solutions ensure optimal performance in harsh environments. Cost-effective and long-lasting.

- 304/304L, 316/316L – Excellent corrosion resistance for marine, chemical, and food processing

- 17-4PH (630) – Precipitation hardening grade for high strength applications

- 2205 Duplex – Superior chloride resistance for offshore applications

- CF8/CF8M – Cast equivalents of 304/316 with enhanced castability

Carbon & Low Alloy Steels

Carbon and low alloy steel castings deliver exceptional strength and wear resistance for heavy-duty applications. Produced via sand or investment casting, they’re ideal for mining, construction, and power generation components. Grades like AISI 1020 to 4340 offer customizable properties through heat treatment. Provides cost-effective solutions for complex, high-stress parts with good machinability.

- A216 WCB/WCC – General purpose valves and fittings

- A352 LCB/LCC – Low temperature service applications

- 4140/4340 – High strength structural components

- 8630 – Heavy section, high integrity castings

Tool & Die Steels

Tool and die steel castings provide exceptional hardness, wear resistance, and thermal stability for precision tooling applications. Produced through specialized casting techniques, these high-performance alloys (including D2, H13, and A2 grades) maintain dimensional stability under extreme conditions. Ideal for molds, dies, cutting tools, and industrial components requiring superior durability and fatigue resistance.

- H13 – Hot work tooling applications

- P20 – Plastic injection molds

- D2 – Cold work tooling

- S7 – Shock-resistant applications

Nickel-Based Alloys

Nickel-based alloy castings deliver outstanding corrosion resistance and high-temperature performance for extreme environments. Utilizing alloys like Inconel, Hastelloy, and Monel, these precision castings serve aerospace, chemical processing, and energy sectors. Excellent creep resistance and mechanical strength are maintained from cryogenic to 1200°C. Ideal for turbine blades, valves, and reactor components.

- Inconel 625/718 – High temperature aerospace components

- Hastelloy C276 – Extreme corrosion resistance

- Monel 400/K500 – Marine and chemical processing

- Alloy 20 – Sulfuric acid service applications

Specialty Alloys

Specialty alloy castings provide unique material solutions for extreme operating conditions. These advanced metallurgical formulations (including cobalt, titanium, and custom alloys) offer exceptional properties like bio-compatibility, EMI shielding, or ultra-high strength-to-weight ratios. Precision-cast for aerospace, medical, and defense applications where conventional materials fail.

- Cobalt Chrome – Medical implants and wear components

- Aluminum Bronze – Marine propellers and bearings

- Titanium – Aerospace and medical applications

- Copper Alloys – Electrical and thermal applications

Each material is supplied with full material certification including chemical analysis and mechanical property data to ensure compliance with international standards such as ASTM, EN, DIN, and JIS specifications.

Advanced Investment Casting Production Methods

We employ two primary techniques, selected based on part requirements and quality specifications:

1. Silica Sol Investment Casting (Premium Process)

✔ Superior Dimensional Accuracy – Capable of holding ±0.003 in/in tolerances

✔ Exceptional Surface Finish – Typically 120-150 RMS as-cast

✔ Thinner Walls Possible – Down to 0.020″ achievable

✔ Better Detail Reproduction – Sharp corners and fine features

✔ More Environmentally Sustainable – Reduced waste generation

✔ Longer Mold Life – Consistent quality over production runs

2. Water Glass Investment Casting (Economy Process)

✔ Lower Production Costs – Reduced material expenses

✔ Faster Cycle Times – Increased production throughput

✔ Adequate for Less Demanding Applications – Where premium finish isn’t critical

✔ Suitable for Larger Parts – More economical for big components

Approximately 85% of our production utilizes silica sol casting to deliver premium quality components, while water glass processing is reserved for simpler geometries or cost-sensitive applications where absolute precision is less critical.

Detailed Step-by-Step Investment Casting Process

Step 1: Advanced CAD Design & Engineering Review

- Initial 3D model creation using SolidWorks, Pro/E, or CATIA

- Design for Manufacturability (DFM) analysis

- Draft angles, wall thickness, and shrinkage compensation

- Simulation of mold filling and solidification patterns

- Customer approval of final design before tooling

Step 2: Precision Tooling Fabrication

- CNC-machined aluminum or steel pattern molds

- Multi-cavity molds for high volume production

- Core boxes for internal features when required

- Certified tooling inspection and validation

Step 3: Wax Pattern Production

- Automated wax injection machines for consistency

- Strict temperature and pressure controls

- Dimensional verification of wax patterns

- Wax assembly into clusters (trees) for efficiency

Step 4: Ceramic Shell Building Process

- Primary slurry dip with high-zircon content

- Secondary slurry with alumina-silicate base

- Robotic dipping systems for uniformity

- Controlled drying between layers

- Final shell thickness of 6-12mm depending on part size

Step 5: Advanced Dewaxing Technology

- High-pressure autoclave dewaxing systems

- Flash fire furnaces for complete wax removal

- Wax recovery and recycling systems

- Shell inspection prior to firing

Step 6: Mold Firing & Preparation

- Computer-controlled furnaces

- Gradual heating to 1800°F (982°C)

- Thermal stabilization before pouring

- Real-time temperature monitoring

Step 7: Precision Metal Pouring

- Vacuum-assisted pouring for critical parts

- Tilt pouring technology for thin sections

- Automated pouring systems for consistency

- Spectrometer analysis of each heat

Step 8: Controlled Solidification

- Directional solidification techniques

- Chill plates for critical sections

- Controlled cooling rates to prevent stress

- Real-time thermal monitoring

Step 9: Shell Removal & Finishing

- Vibratory shell removal systems

- High-pressure water jet cleaning

- Cutting from cluster via band saw or abrasive wheel

- Gate removal and rough grinding

Step 10: Comprehensive Quality Control

- First article inspection reports

- Statistical process control monitoring

- Full dimensional layout inspection

- Non-destructive testing as required

- Mechanical testing of sample castings

Step 11: Value-Added Post Processing

- Heat treatment – annealing, quenching, tempering

- Precision machining – CNC milling, turning

- Surface enhancement – polishing, grinding

- Special coatings – plating, painting, anodizing

Step 12: Protective Packaging & Logistics

- Custom packaging solutions

- Anti-corrosion treatments

- Barcode tracking systems

- Global shipping expertise

Industry-Specific Applications

Our investment castings serve critical functions across multiple high-tech industries:

Aerospace & Defense

- Turbine blades and vanes

- Engine structural components

- Landing gear parts

- Missile and satellite components

Automotive & Transportation

- Turbocharger housings

- Transmission components

- Suspension parts

- Fuel system elements

Medical & Dental

- Surgical instruments

- Orthopedic implants

- Dental prosthetics

- MRI-compatible components

Energy & Industrial

- Valve bodies and trim

- Pump impellers and casings

- Power generation components

- Oilfield tooling

Food Processing & Marine

- Corrosion-resistant fittings

- Sanitary system components

- Marine hardware

- Desalination equipment

Why Partner With ChinaMetalCastings?

Technical Expertise

- Over 20 years of specialized experience

- Engineering staff with advanced degrees

- Continuous process improvement

- Cutting-edge simulation capabilities

Quality Commitment

- ISO 9001:2015 certified

- Nadcap accreditation in progress

- Customer-specific quality plans

- Complete documentation packages

Production Capacity

- 15,000+ square meter facility

- Annual capacity of 5,000+ tons

- Vertical integration capabilities

- Flexible production scheduling

Customer Service

- Dedicated project management

- Multilingual support team

- Transparent communication

- On-time delivery commitment

Contact Us for Your Investment Casting Needs

Whether you require prototype development or high-volume production, ChinaMetalCastings delivers high-precision, cost-optimized lost wax castings tailored to your exact specifications.

📞 Speak With Our Engineering Team Today!

📧 Email: sales@chinametalcastings.com

🌐 Website: https://chinametalcastings.com/

Let’s collaborate to transform your designs into high-performance metal components with uncompromising quality!