Die casting mold

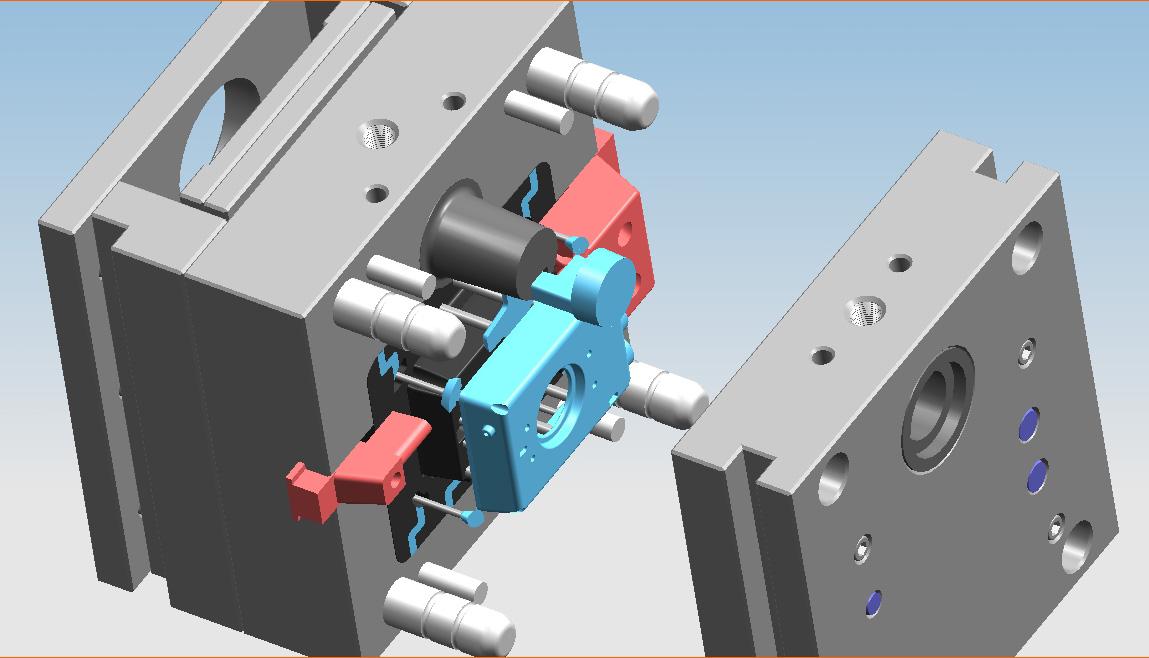

Construction of Diecast mold

Die casting mold consists of two parts, covering part and moving part. The part they combine is called parting line. In hot chamber die casting, the cover part has a gate, while in cold chamber die casting it is an injection port.

The molten metal can enter the mold from here, and the shape of this part matches the injection nozzle in the hot chamber die casting or the injection chamber in the cold chamber die casting.

The moving part usually includes the push rod and the flow channel, which is the channel between the gate and the mold cavity through which the molten metal enters the mold cavity. The covering part is usually connected to the fixed pressing plate or front pressing plate, while the movable part is connected to the movable pressing plate.

The cavity is divided into two cavity inserts, which are independent components and can be removed or installed from the mold relatively easily by bolts.

How Diecast mold working

The mold is specially designed so that the casting remains in the moving part when the mold is opened. In this way, the push rod of the movable part will push out the casting. The push rod is usually driven by the pressing plate. It will accurately drive all the push rods at the same time with the same force, so as to ensure that the casting will not be damaged.

When the casting parts is pushed out, the pressing plate shrinks and retracts all push rods to prepare for the next die casting. Because the casting is still in a high temperature state when demoulding, only when the number of push rods is enough, can the average pressure on each push rod be small enough to prevent damage to the casting.

However, the pusher will still leave traces, so it must be carefully designed so that the position of the pusher will not have too much impact on the operation of the casting.

Diecast mold component

Other parts of the mold include core slide plate, etc. Cores are components used to make holes or openings in castings, and they can also be used to add details to castings. There are three types of cores: fixed, movable and loose.

The direction of the fixed cores is parallel to the direction of the casting coming out of the mold. They are either fixed or permanently connected to the mold.

The movable core can be arranged in any direction other than the out direction. Before opening the mold after solidification, the movable core must be taken out from the mold cavity by using the separating device.

The slide block is close to the movable core, the biggest difference is that the slide block can be used to make the concave surface. Using core and slide block in die casting will increase cost greatly. Loose cores, also known as knockouts, can be used to make complex surfaces, such as threaded holes.

Before the start of each cycle, the sliders need to be installed manually before being pushed out together with the casting. Then take out the loose core. Loose core is the most expensive core because it requires a lot of labor to make and it increases cycle time.

The discharge port is usually thin and long (about 0.13MM), so the molten metal can be cooled quickly to reduce waste. The riser is not needed in the die casting process, because the molten metal pressure is very high, which can ensure the continuous flow from the gate into the mold.

Feature of Die casting

Due to the temperature relationship, the most important material characteristics for the mold are thermal vibration resistance and softness. Other characteristics include hardenability, machinability, thermal cracking resistance, weldability, usability (especially for large mold) and cost.

The mold life directly depends on the temperature of the molten metal and the time of each cycle. The die for die casting is usually made of hard tool steel, because the cast iron can not bear the huge internal pressure, so the die is expensive, which also leads to high cost of opening. The metal to be die cast at higher temperatures requires the use of harder alloy steel.

The main defects in die casting include wear and erosion. Other defects include thermal cracking and thermal fatigue. When there are defects on the surface of the die due to too large temperature change, hot cracking will occur. When too many times are used, the defects on the surface of the die will produce thermal fatigue.