Die Casting,Investment Casting, CNC Machining China

If you are looking for a reliable metal casting manufacturer in China, you come to right place.We are located in Ningbo, where is well know for castings industry.There are thousand of factory and foudry small or big for all kinds of casting items.

We committed to provide customer one-stop services for their new project,which help customer to save their time and money.Through many years efforts,we have enriched our production range of castings and have smooth and close contact with our subsidiary factory.

There are many kinds of metal castings.Mainly, we offer the casting services as follow,

Die Casting

Die casting is an advanced manufacturing process that involves the injection of molten material into a carefully designed mold cavity. This innovative approach shares similarities with other molding and casting techniques, yet stands out due to its unique characteristics. The use of high-quality hardened tool-steel components enables the precise alignment and closure of the mold cavity through the application of hydraulic pressure. This ensures a perfect seal and guarantees the accuracy of the final product.

During the die casting process, certain parts may necessitate the heating of the tooling, while others achieve optimal results when the mold cavity remains cold. This flexibility allows for customized production based on the specific requirements of the desired components. By carefully controlling the temperature and pressure variables, manufacturers can achieve outstanding results in terms of dimensional accuracy and surface finish.

It offers numerous advantages, including high production efficiency and the ability to create complex shapes and intricate details. This technique is particularly well-suited for mass production, as it enables the rapid production of large quantities of components with consistent quality. Additionally, the versatility of die casting extends to a wide range of materials, such as aluminum, zinc, and magnesium alloys, allowing for diverse applications across various industries.

Sand Casting

In general sand casting, sand is used as the mold material, also known as sand casting, sand turning, including wet sand, dry sand and chemical hardening sand. However, not all sand can be used for casting. The advantage is that the cost is low, because the sand used in the mold can be reused; the disadvantage is that the production of the mold is time-consuming, the mold can not be reused, and the finished product can only be obtained after damage.

1.1 sand mold (core) casting method: wet mold sand mold, resin self hardening sand mold, water glass sand mold, dry mold and surface dry mold, solid mold casting, negative pressure mold.

1.2 manufacturing method of sand core: it is selected according to the size, shape, production batch and specific production conditions of sand core. In production, it can be divided into manual core making and machine core making.

Investment Casting And Die Casting

Special casting can be divided into two types according to the molding materials.

-Special casting with natural mineral sand as the main molding materials (such as investment casting, mud casting, shell casting, negative pressure casting, solid casting, ceramic casting, etc.)

-Special casting with metal as the main molding materials (such as metal casting, pressure casting, continuous casting, low pressure casting, centrifugal casting, etc.)

2.1 metal mold casting

The mould is made of metal with higher melting point than raw material. It is divided into gravity casting, low pressure die casting and high pressure casting.

The metals that can be cast are also limited by the melting point of the mold.

2.2 dewaxing casting method

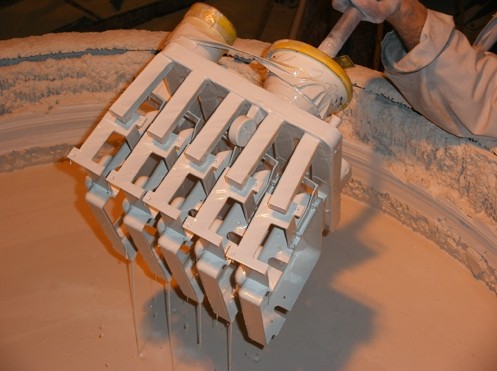

This method can be used for outer film casting and solid casting.

Firstly, the wax is used to copy the casting objects.And then the wax is immersed in the pool containing the ceramic (or silica sol) and allowed to dry. So that the wax replica is covered with a ceramic outer film, and the steps are repeated until the outer film is enough to support the casting process (about 1 / 4 inch to 1 / 8 inch)

Then the wax in the mold is melted and the mold is removed. After that, the mold needs to be high temperature for many times to enhance the hardness before it can be used for casting.

This method has good accuracy and can be used for casting high melting point metals such as titanium. However, due to the high price of ceramics, and the need for multiple heating and complex production, the cost is quite expensive.

Your custom casting supplier

If you have any inquiry for metal casting parts,please send us drawing in 2D or 3D or samples.We will try our best to reply and quote you within 24 hours.

Besides of full range of casting ability, we also regards the quality is top important element for manufacturer.We have our many advance inspection equipment for many quality testing from the material to final products,such as spectrometer, tensile test machine, hardness test machine,CMM dimension report and so on.

Not only prices and quality, it’s very convenience for delivery from our place.for small order, we can ship by express,such as TNT, Fedex,DHL,and so on, for big order ,we mainly ship by Sea.We ship from Ningbo port or Shanghai port .Both of them is very famous and big sea port in China.

CNC Machining

We have many years of CNC machining experience, and are committed to the processing of various precision metal and plastic parts with drawings and samples, as well as the development and production of non-standard fasteners, as well as the development and manufacture of other types of new products. Our technical processing capabilities include engineering fasteners, turning, milling, CNC lathe processing, CNC milling, and automatic lathe processing