High Precision Stainless Steel CNC Machining Parts

We are professional CNC precision machining factory located in Ningbo, China. Since its establishment, it has been committed to this field. Our main business is High Precision Stainless Steel CNC Machining Parts, injection molding, die casting and stamping parts. Now, we have precision CNC machining centers, engraving and drilling machines, lathes and milling machines, wire cutting and other equipment. Through these machines and experienced employees, we can achieve repeat positioning accuracy within a tolerance of 0.005mm, which provides a strong guarantee for precision parts. In all aspects of the product manufacturing process, we have exceeded customer expectations and are aware of our great responsibility to customers, employees, suppliers and society. We will continue to use advanced production equipment to improve efficiency, ensure high and stable quality, and further reduce production costs. The purpose is to create reliable, feasible and reasonably priced molds,CNC machining parts and fast sample services for each industry.

We are professional CNC precision machining factory located in Ningbo, China. Since its establishment, it has been committed to this field. Our main business is High Precision Stainless Steel CNC Machining Parts, injection molding, die casting and stamping parts. Now, we have precision CNC machining centers, engraving and drilling machines, lathes and milling machines, wire cutting and other equipment. Through these machines and experienced employees, we can achieve repeat positioning accuracy within a tolerance of 0.005mm, which provides a strong guarantee for precision parts. In all aspects of the product manufacturing process, we have exceeded customer expectations and are aware of our great responsibility to customers, employees, suppliers and society. We will continue to use advanced production equipment to improve efficiency, ensure high and stable quality, and further reduce production costs. The purpose is to create reliable, feasible and reasonably priced molds,CNC machining parts and fast sample services for each industry.

Custom CNC Machining Parts

|

Available Drawings Format

|

stp, step, igs, iges, x_t, sat, stl, sldxml, prt, ipt, dxf, dwg, PDF, jpg, jpeg, png, etc.

|

|

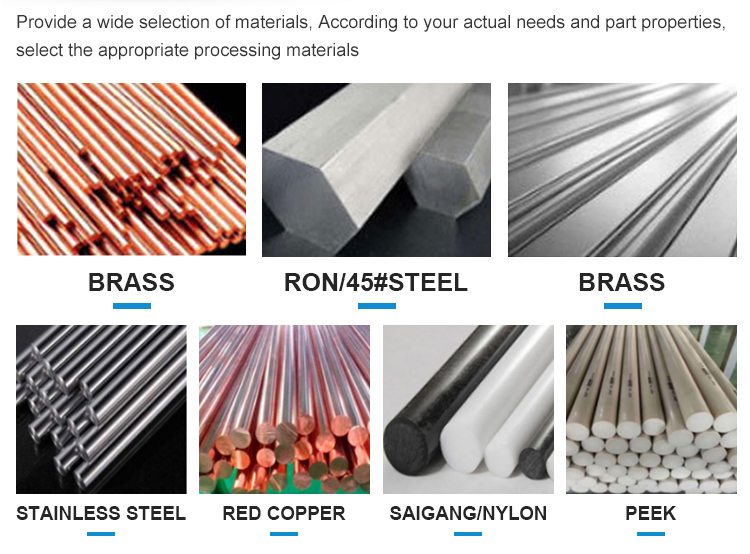

Raw Material

|

1. metal:aluminum: 2024,5052,6061,6063,6082,7075 etc.

Steel: carbon steel (No.10,15,20,25,30,35,40,45…80).etc. alloy steel (15Cr,20Cr,42CrMo) and other etc. Stainless steel: 201,202,301,302,303,304,316,317,420,430,440,630 etc. Brass,copper,bronze:H62,H65.H90,HA177-2,HPb59-1, HSn70-1 etc. Titanium:TA1 ,TA2,TA3,TA4,TA5,TC1,TC2,TC3,TC4,TC5 etc. 2. plastic: ABS,POM,PE,PP,PVC,PC,PMMA,PPS,nylon,acrylic,bakelite etc. 3. others: carbon fiber,fiberglass, wood, hard rubber,PU, etc. |

|

Manufacturing Service

|

CNC machining,milling,turning,grinding, wire EDM cutting,cnc prototype/jig/fixture,laser cutting,other metal fabrication,like

Stamping,Bending,Casting.etc. |

|

Tolerance

|

highest = +/-0.005mm or +/- 0.0002 inch

|

|

Surface Roughness

|

Ra0.4 (milled or turned without polishing or grinding)

|

|

Finish

|

polishing,mirror polishing,brushing, sandblasting, heat treatment etc.

|

|

anodizing,blackening,electroplating(zinc,nickel,chrome),electrophoresis, painting,powder coating,passivate,carburize etc.

|

|

|

Logo

|

laser engraving, CNC engraving, screen-printing etc.

|

Surface Treatment Technology

Processing Material

High Precision Stainless Steel CNC Machining Parts Packaging & delivery

Packaging Details

bulk package or blister tray

Custom Cnc Turning Processing Stainless Steel Joint

Port:Ningbo,Shanghai and others

Lead time:

Quantity(pieces) 1 – 5000 >5000

Lead time (days) 15 To be negotiated