The Advantages of Plastic Plate CNC Machining

Plastic plate CNC machining is a process that involves the use of computer numerical control (CNC) machines to create precise and accurate plastic parts. This process has become increasingly popular in recent years due to its many advantages over traditional machining methods. In this article, we will explore the benefits of it and why it is the preferred method for many industries.

Plastic plate CNC machining is a process that involves the use of computer numerical control (CNC) machines to create precise and accurate plastic parts. This process has become increasingly popular in recent years due to its many advantages over traditional machining methods. In this article, we will explore the benefits of it and why it is the preferred method for many industries.

What is Plastic Plate CNC Machining?

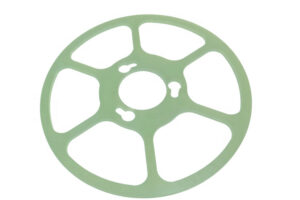

It is a process that involves the use of CNC machines to create plastic parts. The process begins with a computer-aided design (CAD) file, which is used to program the CNC machine. The machine then uses a cutting tool to remove material from a plastic plate, creating the desired shape and size of the part.

Advantages

1. Precision and Accuracy

One of the biggest advantages of it is its precision and accuracy. CNC machines are capable of creating parts with extremely tight tolerances, which means that the parts are made to exact specifications. This level of precision is not possible with traditional machining methods, which rely on manual labor and are prone to human error.

2. Speed and Efficiency

Another advantage of it is its speed and efficiency. CNC machines are capable of producing parts much faster than traditional machining methods, which means that production times are greatly reduced. This is especially important for industries that require large quantities of parts to be produced quickly.

3. Cost-Effective

It is also cost-effective. While the initial investment in CNC machines may be higher than traditional machining methods, the long-term cost savings are significant. CNC machines require less labor and produce less waste, which means that production costs are lower.

4. Versatility

It is also highly versatile. CNC machines can create parts in a wide range of shapes and sizes, and can work with a variety of plastic materials. This makes it an ideal method for industries that require a high degree of customization and flexibility.

5. Consistency

Finally, plastic plate CNC machining is highly consistent. CNC machines are programmed to create parts to exact specifications every time, which means that the parts are consistent in quality and performance. This is especially important for industries that require parts to meet strict quality standards.

Conclusion

In conclusion, plastic plate CNC machining is a highly effective method for creating plastic parts. Its precision, speed, cost-effectiveness, versatility, and consistency make it the preferred method for many industries. If you are in need of plastic parts, consider using our CNC Machining services for your production needs.