Investment Casting Coating

Introduction

Investment casting, also known as lost-wax casting, is a precision manufacturing process used to produce complex metal parts with high dimensional accuracy and excellent surface finish. A critical component of this process is the investment casting coating, which plays a vital role in ensuring the quality of the final castings. ChinaMetalCastings is a leading professional Investment Casting and CNC Machining manufacturer in China, specializing in high-performance coatings and advanced casting solutions.

This article provides an in-depth analysis of investment casting coatings, covering their types, properties, viscosity measurement methods, and their impact on shell mold quality.

1. Types of Investment Casting Coatings

Investment casting coatings are primarily classified into two categories based on their binder systems:

1.1 Sodium Silicate (Water Glass) Coating

Sodium silicate-based coatings, commonly referred to as water glass coatings, are widely used in investment casting due to their cost-effectiveness and ease of application. The key properties of water glass coatings include:

-

Viscosity – Affects shell strength and surface finish.

-

Fluidity – Determines how well the coating spreads over the wax pattern.

-

Coverage – Ensures uniform layer deposition.

-

Suspension Stability – Prevents particle settling.

Factors Influencing Water Glass Coating Viscosity

-

Modulus of Sodium Silicate – Higher modulus increases viscosity.

-

Density – Higher density leads to greater viscosity.

-

Temperature – Rising temperature reduces viscosity.

-

Powder-to-Liquid Ratio – Higher ratios increase viscosity.

-

Particle Shape & Distribution – Angular powders increase viscosity, while rounded particles reduce it. Monomodal (single-peak) particle distribution increases viscosity, whereas bimodal distribution lowers it.

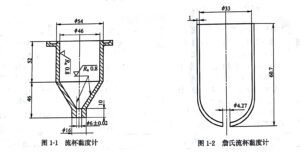

Viscosity is typically measured using a flow cup viscometer (100 mL capacity, 6 mm outlet diameter).

1.2 Silica Sol Coating

Silica sol (colloidal silica) coatings exhibit dilatant (shear-thickening) behavior, meaning their viscosity increases under shear stress. Due to their higher density and viscosity compared to water glass coatings, they retain a thicker layer on the wax pattern.

Key Characteristics of Silica Sol Coatings

-

Higher Powder-to-Liquid Ratio – Required for sufficient coating thickness.

-

Density & Viscosity Control – More critical than measuring coating weight.

-

Zahn Cup Viscometer (No. 4) – Standard tool for viscosity measurement (44 mL capacity, 4.27 mm outlet).

A comparison of Zahn Cup #4 and #5 viscosity data is provided in the reference table.

2. Viscosity Measurement Methods

Proper viscosity control is essential for coating performance. The standard measurement procedure includes:

-

Immersion – Dip the viscometer cup into the slurry at a slight angle.

-

Withdrawal – Lift vertically at a steady speed to avoid shear effects.

-

Timing – Start the timer when the coating stream breaks 10 mm below the cup outlet for minimal error.

3. Impact of Coating on Shell Mold Quality

The coating directly influences:

-

Surface Finish – Lower viscosity in face coats reduces defects.

-

Shell Strength – Higher viscosity in reinforcement layers improves durability.

-

Dimensional Accuracy – Uniform coating prevents distortion.

4. ChinaMetalCastings: Your Trusted Investment Casting Partner

As a premier Investment Casting and CNC Machining manufacturer in China, ChinaMetalCastings offers:

-

Advanced Coating Solutions – Optimized for water glass and silica sol systems.

-

Precision Castings – High-quality aerospace, automotive, and industrial components.

-

CNC Machining Services – Post-casting machining for tight-tolerance parts.

Conclusion

Investment casting coatings are a cornerstone of the lost-wax process, dictating mold strength and casting quality. By understanding viscosity control and coating selection, manufacturers like ChinaMetalCastings deliver superior metal components. For expert Investment Casting and CNC Machining services, contact us today!