Analysis of Key Technology of Aluminum Die Casting Parts

Abstract: With the rapid development of modern automobile industry, the application of light metal materials, represented by a-luminum alloy, is becoming more and more popular. In order to guarantee the qualified rate of production, the quality requirement of aluminum alloy parts is higher and higher. However, due to the defects in casting technology, the quality of aluminum alloy castings has not been effectively resolved. Taking aluminum alloy shell castings as an example, the process and flow of die casting technology for aluminum alloy parts are described in detail, and some suggestions are put forward to improve the production quality of aluminum alloy parts.

As people’s awareness of environmental protection has increased, the automobile manufacturing industry has taken the production of low-fuel consumption ordinary cars as the main direction since the 1980s. Economy, light weight and miniaturization have become the main characteristics of modern cars. In order to meet the requirements of the new trend of automobile production, various iron castings in automobile manufacturing have begun to be replaced by aluminum castings, thus realizing the requirements of modern automobile lightweight. With the extensive use of aluminum alloy castings, the production quality of related castings has also received extensive attention. Due to the imperfect die-casting technology of aluminum alloy parts, the quality of aluminum alloy parts has never reached the ideal state. Therefore, in recent years, the research and development work on the key technology of aluminum alloy parts die-casting has not stopped.

Overview of aluminum alloy shell castings

Aluminum alloy shell castings are commonly used in the modern automobile industry. Due to their irregular shapes, it is difficult for some structures to meet the quality standards through mechanical processing. Therefore, some aluminum castings are only used for the rough surface structure of automobile shells. From the perspective of the safety of automobile use, the industry has very strict quality requirements for aluminum castings. All castings have strict standards for material strength. In the requirements for shell castings, surface, Double standards of internal quality. In order to ensure product quality, some manufacturers have adopted optical flaw detection technology to control the entire production process.

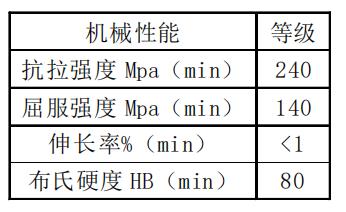

Table 1 Performance table of aluminum alloy shell castings

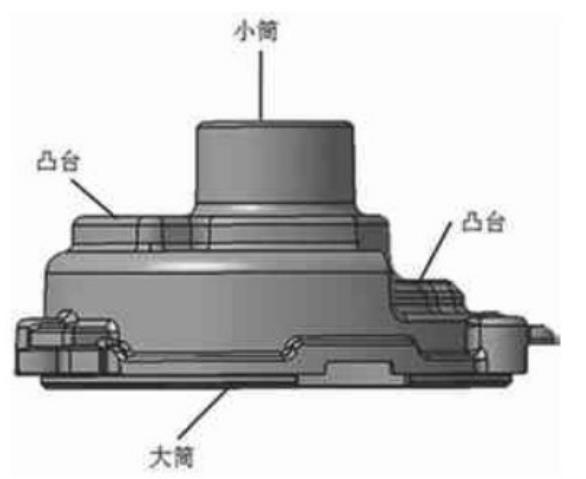

The aluminum alloy shell cover introduced in this article has a relatively simple structure and only two parts need to be machined. However, due to the irregular shape of the shell, the heights of the two bosses are different. Among them, the maximum outer diameter, height, The main wall thickness sections are 105mm, 40mm and 3.5mm respectively. The parts that need to be machined are the outer diameter surfaces of the large and small shells. The machining tolerances must be controlled within +/-0.1mm. Since this part does not need to process the inner cavity, the difficulty of die casting is relatively small.

Figure 1 Schematic diagram of aluminum alloy shell castings

In order to ensure that the performance of the casting can meet the requirements of withstanding the static crushing force above 20kN, the production process needs to be controlled in accordance with GB6414-86 CT6 to ensure that the casting is free of impurities and cracks during the die-casting process, and welding is not allowed. Repair the product by repairing or dipping.

Product process analysis

2.1 Production process

The production process of parts is: incoming material → melting/die casting → trimming/cleaning → machining → cleaning → assembly.

2.2 Defect analysis

Although the aluminum alloy shell casting introduced in this article has a simple structure, the following production defects often occur during the production process:

(1) Variegation: The temperature difference between the metal and the mold, the filling speed during smelting, and the size of the spray amount during the shot peening process are not well controlled, which easily causes the color of the casting to become dark and black.

(2) Porosity defects: This type of problem can hardly be completely avoided in the production process of aluminum alloy castings. The control requirement for the porosity problem of the casting is to ensure the overall strength of the shell, and it is necessary to ensure that the critical area does not produce porosity that exceeds the ASTME505 level 2 standard. The acceptable diameter range of the pores in the casting is ≤∉1.6mm, the pore rate should be controlled within 6.2%, and the diameter of the pores on the machined surface should not be greater than 2.0mm.

In terms of production quality control, the visual inspection is mainly responsible for the inspection of the appearance defects of the castings, and the X-ray inspection is responsible for the control of the internal quality of the castings. However, in mass production, from the perspective of accelerating production speed and controlling production costs, these two methods have certain defects. Therefore, the aluminum alloy die-casting process is analyzed and referenced with CAE and other auxiliary technologies in order to improve the inherent quality of the castings. Problem control is handled in the rough stage.

2.3 Process parameters and equipment selection

According to the structural characteristics and production requirements of the casting, the casting pressure is set at 350T. According to the production experience of similar products in the past, such as unreasonable mold combination and improper selection of process parameters, the problem of excessive liquid metal filling speed will occur during the die casting process. , Resulting in the obstruction of gas discharge in the cavity, and eventually forming quality defects such as pores or excessive oxide impurities in the finished product, which affects the pass rate of the casting.

According to the design requirements of the casting, the thickness of the dense surface layer of the thin-walled shell casting is only 0.8mm. If it is processed properly, the center structure will be loose, which will lead to the reduction of shell performance and pressure resistance. Therefore, when designing the mold, the positioning pin is used to coordinate the positioning and the processing amount is controlled within 0.5mm. This saves machining time and is more conducive to the improvement of the inherent quality of the casting.

2.3.1 Selection of mold program

According to the design requirements of the aluminum alloy shell casting, virtual design was carried out using AnyCast-ing software, and three different inlet design schemes were obtained. Through comparison, the flow channel with smoother flow filling was finally determined. Design plan C is to produce molds, and it is found in actual production that this plan has a better effect on improving the internal defects of the shell castings and increasing the yield of the shell.

2.3.2 Setting of melting temperature

Combined with the structural weight of the casting shell, a 350T cold press chamber die-casting machine is used for the die-casting of the castings, and the temperature is set within the range of 640℃+/-20℃. In order to ensure the pressure of the metal liquid filling process is stable, try to avoid Turbulent flow, splashing and other problems caused by secondary oxidation slag entrainment or erosion of the core, the pressure rise rate is set to 1.3kPa/s.

2.3.3 Purification of alloy liquid

In order to enhance the quality of aluminum alloy shell castings and reduce the impact of pores, pinholes, and slag inclusions on the product qualification rate, a secondary refining step is used in the casting process, that is, the alloy is refined once before and after the furnace is released. At the same time, a fiber filter screen is used at the riser nozzle, a ceramic filter screen is used at the horizontal gate, and a double-layer fiber filter screen is placed at the end of the horizontal gate and the gap opening to perform three-time filtration to control the occurrence of product slag defects. Rate.

Actual production situation and effect

According to the above scheme and process, 6 shell samples were randomly selected for inspection in actual production, and it was found that scheme C has a better effect on improving the internal defects of the shell castings and increasing the yield of the shell. Through X-ray inspection, it was found that the pass rate of internal control reached 100%; the precision turning test found that the porosity index of the machined surface reached the ASTM E505 level 2 level; through the destructive crush test, it was found that all samples could reach Withstand the pressure above 25kN. It can be seen that the aluminum alloy shell casting design and process selection introduced in this article are relatively reasonable, and certain effects have been achieved in controlling product quality.

Conclusion

With the continuous improvement of science and technology and related processes, the die-casting process of aluminum alloy parts has been continuously improved. The traditional related process flow is long, which is not conducive to quality control in the casting process. In order to ensure the improvement of production quality, it is necessary to start quality management from the material stage. The production process and key technologies of the above aluminum alloy shell castings have reached reasonable and feasible standards through scientific design and program selection, which proves that the relevant technologies and processes can meet the quality requirements of mass production for related casting products, and also verify the aluminum alloy The role of key parts die-casting technologies in improving the overall quality of related products.