Appearance quality standard of silica sol castings

With the development of China’s foundry industry and the improvement of foundry technology, customers have higher and higher requirements for foundry factories. We foundry people can understand the mentality of customers. Backwardness will be eliminated. We have been adhering to the business philosophy of customer first and strive to meet the needs of customers. Many customers who do not know much about castings do not understand the appearance defects of products, and naturally think that the cast products should be free of defects. Today, we mainly talk about the appearance quality judgment standard of casting blank by silica sol casting process.

1. Cold lap

the reason for the formation of cold lap is generally the low temperature of molten iron and slow pouring speed, resulting in the condensation of molten steel before fully filling the mold shell in the places with small casting structure, resulting in the casting defects of small structure. Cold insulation will reduce the strength of the casting, affect the mechanical properties of the casting, and even break the casting in serious cases. Therefore, cold insulation is absolutely not allowed on the casting surface of silica sol castings.

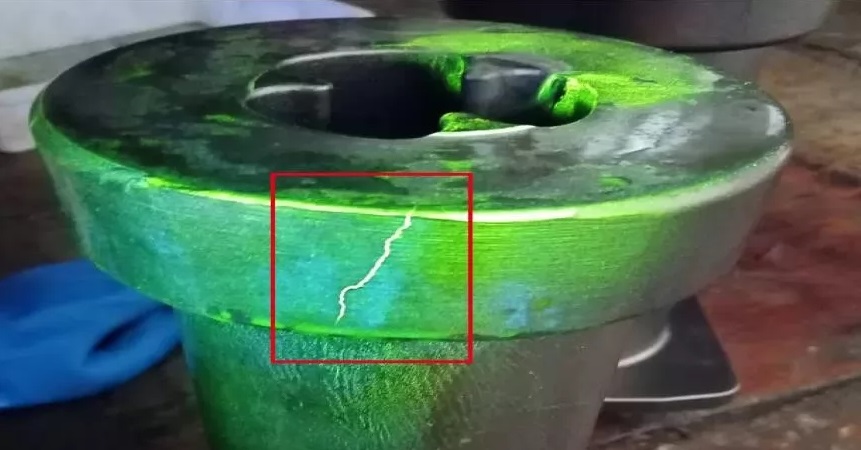

2. Crack

the cause of the crack is that the shrinkage is blocked due to the inconsistent cooling rate of each part during the solidification shrinkage of the casting. When the resistance exceeds the material strength limit, the casting will produce a crack. The damage of crack is similar to that of cold shut, which will also reduce the strength and mechanical properties of castings. Therefore, we are not allowed to receive products with cracks on the surface.

3. Insufficient pouring

the insufficient pouring of the casting is generally due to the complex structure of the casting and the small channel in the mold shell, resulting in the lack of molten steel flow to some positions. Insufficient pouring seriously affects the appearance of the casting, so it is also a defect that is absolutely not allowed to be accepted

4. Eyelet

the eyelet contains air hole, sand hole and shrinkage hole. Without affecting the performance of the casting, we Φ One is allowed within 50mm Φ Holes with depth less than 0.5mm. More than one is considered unqualified.

5. Fleshy

fleshy on the surface of the casting is mainly manifested as iron beans, flash and bulge. Fleshy generally will not affect the strength of the casting. Flash and bulge are not allowed on the surface of our silica sol casting! Without affecting the assembly performance of castings, we Φ One is allowed within 50mm Φ Iron beans with height less than 0.5mm. More than one is considered unqualified.

6.Bumping

slight bumps may occur when products collide with each other during shot blasting of castings or after transportation in the plant. Without affecting the assembly performance of castings, we Φ Within 50mm, it is allowed to accept bumps with length of 1mm, width of 0.5mm and depth of 0.5mm.