1.2.2 CNC machine tool working process

When CNC machine tools are machining parts, the machining information such as the geometric data and process data of the workpiece must be compiled into the CNC machining program of the part according to the specified code and format, which is the work order of the CNC machine tool. Input the machining program to the numerical control system in an appropriate way, and the numerical control system processes the data of the inputted machining program, outputs various information and instructions, and controls the speed, start and stop of the main movement of the machine tool, and the direction, speed and displacement of the feed. , and other actions such as tool selection and exchange, workpiece clamping and loosening, cooling and lubricating switches, etc., so that the tool, workpiece and other auxiliary devices work in strict accordance with the order, trajectory and parameters specified in the processing program. The operation of CNC machine tools is in the process of continuous calculation, output, feedback and other control to ensure the accuracy of the relative position between the tool and the workpiece, so as to process the parts that meet the requirements.

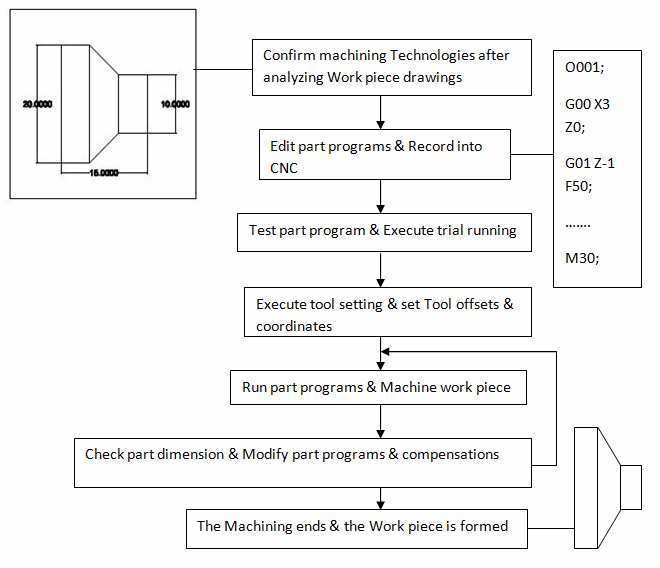

The working process of the CNC machine tool is shown in Figure 1-7. First, the geometric information and process information on the drawing of the machined part should be written into a machining program with the specified code and format, and then the machining program should be input into the numerical control device, according to the requirements of the program. , The numerical control system processes and distributes the information, so that each coordinate moves several minimum displacements, realizes the relative movement of the tool and the workpiece, and completes the processing of the parts.