Custom Die casting housing

As a professional die casting manufacturer, we make all kinds of custom Die casting housing for electric motor.

Sample information

Model Number:RP-ALD-03-004

Application: casting parts ,Machinery Parts

Color:Silver or according to customer’s request

Material:ADC12.A380,A356 and so on

Method:Die casting and CNC Machining

Design Service:According to clients’ requirment

Finish:Powder coating,paint or according to customer

Application:electric motor

Dimension:380 x 160x 22mm

Certification:ISO/TS16949

Our Advantage:

1. We are a professional OEM die casting manufacturer,and 85% worker more 10 years

2. We have experienced engineers and quality control team as our strong backing.

3. High quality, competitive price, quick response is our mission.

4. Professional technical support

5. Good deliver time

6. Strict quality control process,and each samples will be checked by CMM

7. Cost-Effective

8. Rich experience in mould design and die casting

9. ISO/TS16949/ERP system guarantee

Die casting Manufacturer

| Material | 1. Aluminum alloy ADC12,A380,A360,A356,A413, etc 2. Zinc alloy 3#zinc,5#zinc and 8#zinc,etc |

| Designs | 1.As per the customer’s drawings 2.As per the customer’s samples |

| Dimension | Base on the customer’s design |

| Surface treatment | Sand blasting,Power coating,Painting,Anodization,Electrophoresis,Black oxidation,Zinc/Chrome/Nickel plating; |

| Software | Pro/E, Auto CAD, CAXA UG |

| Products | All kinds of aluminum &zinc alloy casting: include automotive parts, monitor parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts, and so on |

| Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance. 2.Third Party inspection available upon requirement |

| Packing | Single protective + Carton + Pallet, each carton less than 20 KGS. |

| Payment | T/T,L/C |

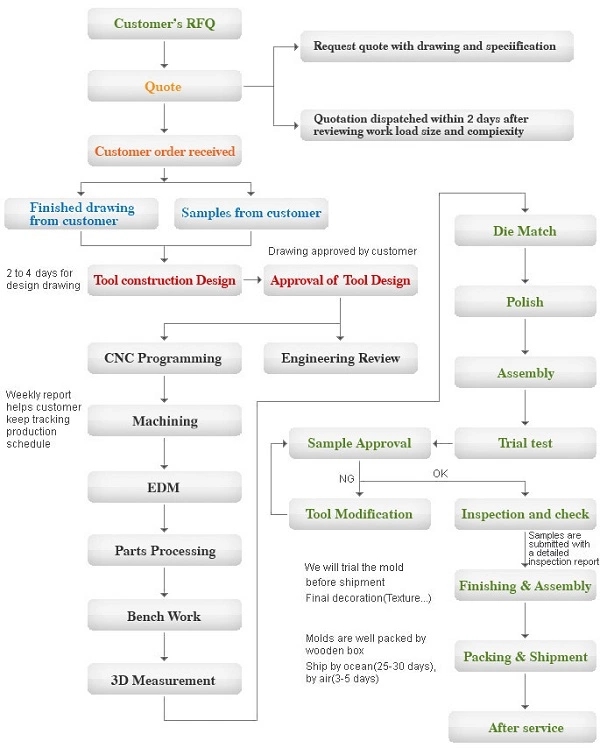

Die casting process diagram

1.– customers provide mould design or sample for us

2.– mutual discuss for the specification of product including the material, special treatment, the price, delivery time, payment term.

3.– provide competitive price for customer and send PI immediately

4.– quick manufacture upon received the down payment

5.– send sample first and batch production for achieved the confirmation of customer

6.– determined by customer’s requirement