Carbon Steel Investment Casting

China Metal Castings is a world-class modern steel foundry renowned for its reliability and precision. We specialize in producing high-quality carbon steel investment castings across a diverse range of materials. Leveraging advanced investment casting technology, we achieve tight dimensional tolerances, reducing costs while ensuring superior performance for your applications.

China Metal Castings is a world-class modern steel foundry renowned for its reliability and precision. We specialize in producing high-quality carbon steel investment castings across a diverse range of materials. Leveraging advanced investment casting technology, we achieve tight dimensional tolerances, reducing costs while ensuring superior performance for your applications.

As a leading manufacturer of carbon steel investment castings, we offer expertise in all carbon steel alloys. When selecting the ideal grade for your project, key considerations include application requirements, machinability, weldability, strength, formability, and corrosion resistance. Unsure which alloy best suits your needs? Our team is ready to assist—contact us to discuss your specific requirements.

Carbon steel is a preferred choice for investment castings due to its cost efficiency, strength, wear resistance, and ease of machining. Various grades of carbon and low-alloy steel are widely used across industries. If you need precision-crafted carbon steel investment castings tailored to your exact specifications, trust China Metal Castings. With years of experience, we deliver high-quality net-shape castings in low-alloy and mild steel, meeting the most demanding standards.

Mechanical Characteristics of Mild and Low Alloy Steel Investment Castings

The following table outlines the mechanical properties of mild (low carbon) steel.

Mild (Low Carbon) Steel

| Alloy | Heat Treatment | UTS (kpsi) | YS (kpsi) | % Elongation | Hardness |

|---|---|---|---|---|---|

| 1018 | Annealed | 50-58 | 30-38 | 28-35 | Rb 75 Max |

| 1022 Modified | Annealed | 80-95 | 55-60 | 12-18 | Rb 95 Max |

The table below presents the mechanical properties of low alloy carbon steel.

Low Alloy Steel

| Alloy | Heat Treatment | UTS (kpsi) | YS (kpsi) | % Elongation | Hardness |

|---|---|---|---|---|---|

| 8620 | As Cast | 70-80 | 50-60 | 18-24 | Rb 95 Max |

| 8620 | Hardened | 110-140 | 85-115 | 8-15 | Rc 28-42 |

| 4130 | As Cast | 80-90 | 60-70 | 14-18 | Rb 95 Max |

| 4130 | Hardened | 140-180 | 110-140 | 4-18 | Rc 25-45 |

| 4140 | As Cast | 90-100 | 70-80 | 14-19 | Rb 95 Max |

| 4140 | Hardened | 140-210 | 110-160 | 4-18 | Rc 22-50 |

| 4340 | As Cast | 90-100 | 70-80 | 14-19 | Rb 95 Max |

| 4340 | Hardened | 140-210 | 110-185 | 4-18 | Rc 22-50 |

Our Expertise in Carbon Steel Investment Castings

We specialize in producing high-precision carbon steel investment castings with exceptional consistency and tight tolerances. Our capabilities include:

- Utilizing advanced melting techniques to ensure uniform hardness and strength in carbon steel castings.

- Performing secondary operations such as precision machining, threading, and applying protective coatings (e.g., plating) to enhance corrosion resistance. Heat treatment is also employed to optimize ductility and strength.

- Our skilled team has extensive experience with various carbon steel grades, and our investment casting process complies with AS9100 and ISO 9001 certifications.

Applications of Carbon Steel Investment Castings

Carbon steel investment castings are widely used across multiple industries, including automotive, defense, oil & gas, mining, and general manufacturing. Common applications include:

- Crankshafts

- Levers and handles

- Mounting brackets

- Firearm mechanisms

- Protective enclosures

- Flow control valves

- Transmission gears

- Spray nozzles

- Support bipods

- Pivot hinges

How Are Carbon Steel Investment Castings Manufactured?

Mold Development

We utilize advanced spectrometers to verify the precise mechanical properties of metal alloys, ensuring optimal performance in every casting.

Wax Pattern Production

Specialized wax injection machines extrude medium-temperature wax into precision molds, forming high-quality wax replicas of the final product.

De-burring the Wax Pattern

Each wax model undergoes meticulous inspection and precision trimming to guarantee flawless dimensional accuracy before further processing.

Pattern Assembly

Following engineered casting designs, individual wax patterns are carefully welded onto central wax runners to create complete casting clusters.

Shell Formation

A multi-layer ceramic coating process builds a heat-resistant shell around each wax assembly through successive dipping and stuccoing applications.

Shell Curing

The ceramic-coated clusters undergo controlled heating in industrial furnaces to achieve optimal strength and thermal stability.

Pouring

Molten steel is precision-poured into the preheated ceramic molds under carefully controlled conditions to ensure complete cavity filling.

Casting Extraction

After solidification, the cast components are separated from the shell structure and prepared for final finishing operations.

Carbon Steel Investment Castings Services

Investment Casting Services

Choosing the optimal manufacturing process for your component is crucial. Investment casting delivers exceptional value when you require intricate geometries with tight dimensional tolerances.

This time-tested technique offers significant economic advantages by consolidating multiple production steps into a streamlined operation, reducing both lead times and manufacturing costs. The process consistently yields components with superior surface finishes that faithfully reproduce mold details, while simultaneously reducing material flaws to ensure outstanding product integrity.

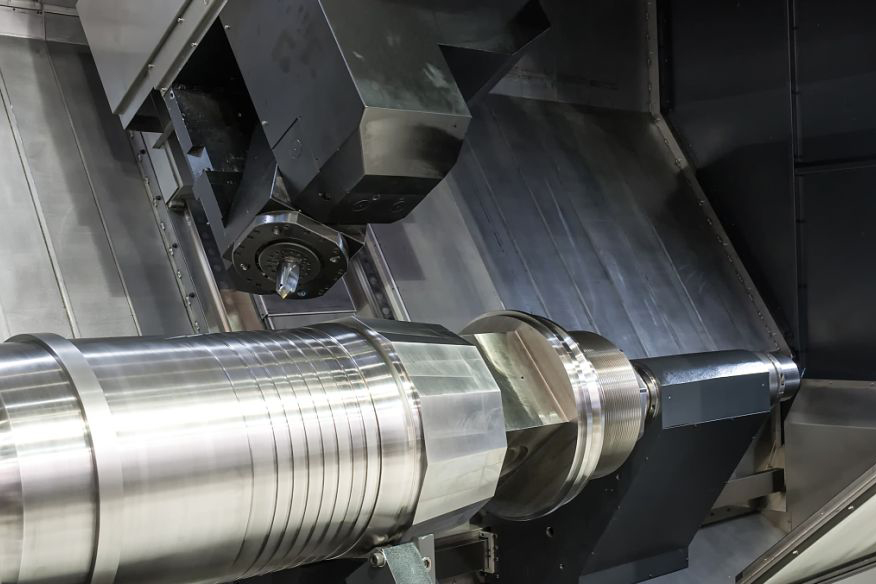

CNC Machining Services

We provide complete precision CNC machining solutions through our advanced manufacturing capabilities, including CNC milling, turning, boring, grinding, drilling, EDM wire cutting, and other specialized processes. Through continuous technological upgrades, our facility now operates:

- 14 high-precision 4-axis CNC machining centers

- CNC gantry milling and boring machines

- CNC horizontal and vertical lathes

- CNC honing equipment

- CNC deep-hole internal grinding systems

- Numerous conventional machining stations

This modern equipment portfolio enables us to handle complex components with exceptional accuracy and efficiency.

Surface Treatment Services

To optimize component performance, durability, and longevity, we provide comprehensive surface enhancement solutions including:

- Shot blasting

- Sand blasting

- Vibratory finishing

- Electro-galvanizing

- Pickling & passivation

- Electro-polishing

- Phosphating

- Black oxide coating

- Brush finishing

- Mirror polishing

Our advanced surface treatments improve corrosion resistance, fatigue strength, and aesthetic quality for superior product performance.

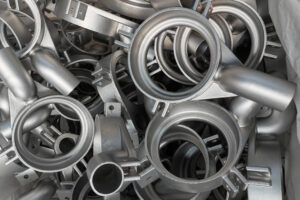

Carbon Steel Investment Casting Products Manufactured for Our Clients

At China Custom Castings, we tailor every project with precision-engineered processes to deliver superior quality, maximum cost efficiency, and exceptional performance.

China Metal Castings Advantages

As a premier investment casting manufacturer, we pursue excellence in every component we produce. Choosing us as your partner delivers significant competitive advantages:

• Precision Manufacturing – We specialize in producing high-tolerance components with exceptional surface finishes that meet your exact technical specifications.

• Cost Efficiency – Our optimized production processes and economies of scale enable us to deliver competitively priced parts without compromising quality.

• Rapid Turnaround – With streamlined operations and advanced facilities, we consistently meet tight delivery schedules.

• Technical Expertise – Our engineering team provides comprehensive support from design optimization to material selection.

• Customer-Centric Service – We maintain open communication and responsive support throughout your project lifecycle.

Specializing in carbon steel, mild steel, and low alloy steel investment castings, we guarantee finished products that precisely match your requirements. Our capabilities cover a wide range of industrial applications where strength, durability and precision are critical.

Interested in learning more about our carbon steel or other alloy casting solutions? Contact us today to speak directly with our technical specialists. They’re standing by to evaluate your project requirements and provide tailored recommendations for optimal results.