Aerospace die casting

Aerospace die casting is the process of creating complex and intricate metal parts used in the aerospace industry. Die casting is a popular manufacturing technique for producing parts with high efficiency, accuracy, and quality. It is used to create various components of aircraft systems, including engine parts, landing gear, wing components, and control systems.

Aerospace die casting is the process of creating complex and intricate metal parts used in the aerospace industry. Die casting is a popular manufacturing technique for producing parts with high efficiency, accuracy, and quality. It is used to create various components of aircraft systems, including engine parts, landing gear, wing components, and control systems.

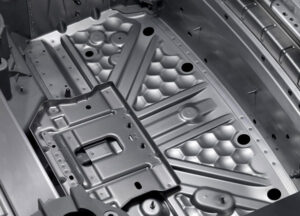

Die casting is a manufacturing method that involves injecting molten metal into a die or mold, allowing it to solidify and take the shape of the mold. Aerospace die casting utilizes a variation of this process called high-pressure diecast (HPDC), which is a more advanced and efficient method. HPDC involves injecting the molten metal into the die at high pressure, forcing it to fill the mold quickly and consistently.

The aerospace industry demands high-quality, lightweight, and durable parts with tight tolerances, and diecast can help achieve these requirements. It ensures that parts have consistency in their shape, size, and strength, making them perfectly suited for use in the aircraft industry. The die casting process also produces parts with excellent surface finishes, reducing the need for additional finishing or polishing.

The materials used in aerospace die casting can vary, depending on the specific components being produced. Magnesium, aluminum, zinc, and copper alloys are commonly utilized in such kind of die casting due to their lightweight and high strength. These alloys come with high melting points, making them the ideal choice for use in engine parts and other high-temperature applications.

The aerospace industry requires adherence to strict quality standards, and aerospace die casting is no exception. Manufacturers must comply with stringent regulations and standards in every aspect of the production process, from material selection to final product inspection. The use of advanced testing and quality control methods is also essential to ensure that the parts meet the required strength, durability, and dimensional accuracy standards.

In summary, It is an essential manufacturing technique for producing high-quality parts used in the aerospace industry. Advanced high-pressure die casting methods result in parts with consistent shapes and sizes, excellent surface finishes and high strength. The aerospace industry requires lightweight and durable components that conform to strict quality standards, and it can provide all of these key requirements. By partnering with an agile and experienced die casting manufacturer, companies can enjoy high-quality, cost-effective, and efficient solutions for producing critical aerospace components.