CAE Analysis in Aluminum Alloy Die Casting Filter

Abstract: With the development of the foundry industry, the structure of aluminum alloy die-casting parts tends to be thinner and more complicated. However, in the high-speed injection process, the rapid completion of the filling of the complex cavity in a short time will inevitably cause the turbulence and gas entrapment of the molten aluminum in the cavity. If the exhaust is not smooth, it is easy to produce pores on the surface and inside of the casting, resulting in poor appearance and internal quality of the casting. A good gating system and exhaust system can effectively reduce the turbulence and gas entrapment of the molten aluminum during the filling process. The rationality of the runner system and exhaust system design will directly affect the quality of the entire casting. The author takes a communication component filter newly developed by our company as an example. Through the use of CAE simulation analysis to simulate the program, the author analyzes the root cause of the stoma Development provides reference and reference.

The development trend of lightweight and functional integration of aluminum alloy die castings has led to the diversification and complexity of the structure of the parts, and there have been more parts with poor die casting processability and uneven wall thickness [1]. For such parts with very large wall thicknesses and very complex structures, during the die-casting production process, due to the rapid intrusion of molten metal and hitting the complex wall, eddy currents and entrainment will inevitably be generated. If the runner system and the overflow system are designed unreasonably, it will be difficult for the gas dissolved in the molten aluminum to be completely discharged from the cavity, which will inevitably lead to pore defects in the interior and surface of the die casting. At the same time, due to the complexity of the part structure, the molten aluminum cannot be effectively fed during the rapid solidification process, resulting in shrinkage porosity in the casting [2] [3]. Such products with pores and shrinkage on the surface and inside cannot meet the technical requirements of the parts, resulting in the scrapping of the parts, which brings great waste to the enterprise.

The author takes a communication component filter as an example, uses CAE to simulate the original plan, analyzes the root cause of the defect, and proposes an optimized plan to effectively solve the problem of product pore defects. This article provides methods and ideas for solving the defects of such die-casting parts, and also provides references for the design of mold pouring and overflow system.

1. Basic introduction of castings

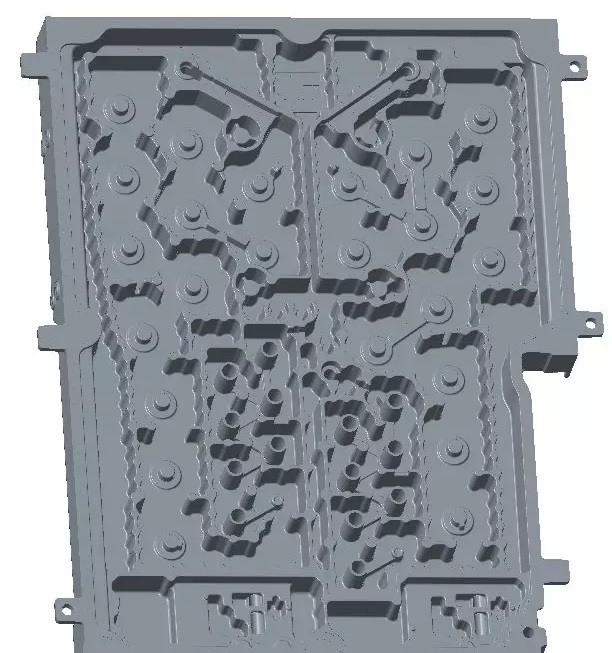

Figure 1 is a structural diagram of a certain communication component filter. The casting mass is 3kg, and the material grade is DC01. The basic size of the casting is 414mm×333mm×38mm, the maximum wall thickness is 4mm, the thinnest wall thickness is 2mm, and the average wall thickness is 3mm. The inner cavity is staggered with ribs similar to the labyrinth structure. It is a relatively complex casting.

This part is a filter used in mobile communication transmitter base stations with high technical content so far. Compared with the traditional filter, its internal cavity structure is more complicated, the labyrinth structure is more and more complicated, the wall thickness is uneven, and there are many columns and mounting holes. The complicated structure will inevitably lead to insufficient filling of the molten aluminum, and the presence of wrapping gas locally in the casting. In addition, the internal compactness of the casting is required to be high, and the product needs to be electroplated. When the casting is electroplated and baked, the gas in the hole is heated and expands, which will cause the surface of the casting to bubble, so appropriate methods should be used to solve the pore defects in the production. Therefore, how to reduce the gas filled into the casting is a difficult point in the design of the entire die-casting process.

Based on the above analysis of the product, the casting of the product is difficult. Studying the filling of the runner system of this product and the exhaust of the overflow system are the first factors to be considered to solve the pore defects.

Figure 1 Structure diagram of the filter

2. Defect description

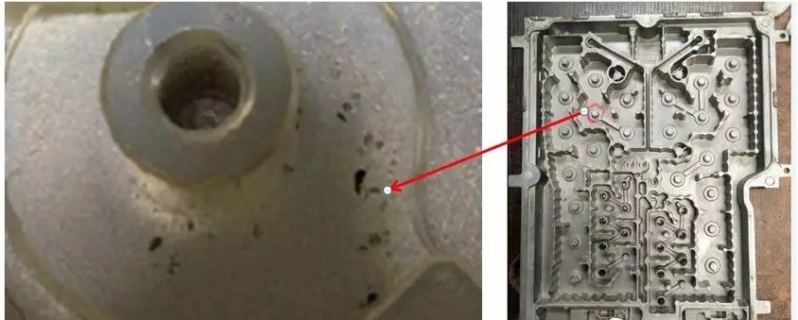

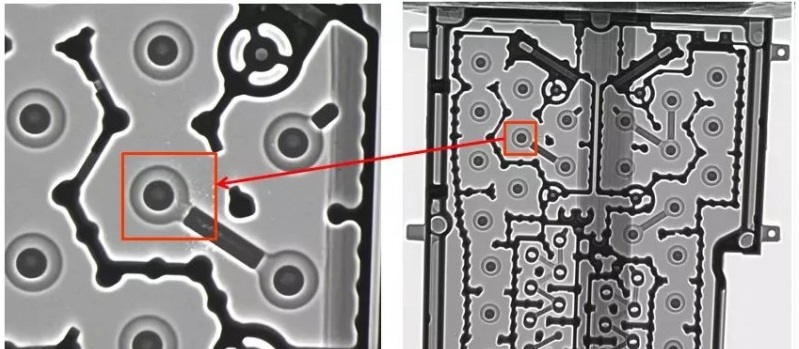

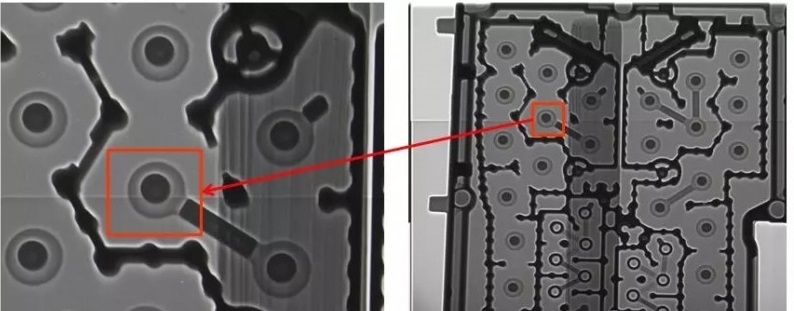

According to the results of die-casting trial production, some irregular pores were found on the peripheral surface of a pedestal at the left end of the casting. The largest pore diameter is 3mm, and the smallest is 0.5mm. The pores are mostly round and elliptical, some of them are elongated, and the inside of the hole is smooth (see Figure 2). After X-ray machine inspection, it is found that the air holes are clustered together and distributed around the pedestal. The internal quality of X-ray is shown in Figure 3. Therefore, it can be preliminarily judged that the pore defect is caused by gas accumulation, and the product rejection rate caused by the defect in production reaches 27.8%.

Figure 2 Diagram of stomatal defects

Figure 3 X-ray stomatal defect map

Figure 3 X-ray stomatal defect map

3. Analysis of the causes of stomatal defects

3.1 Product structure analysis

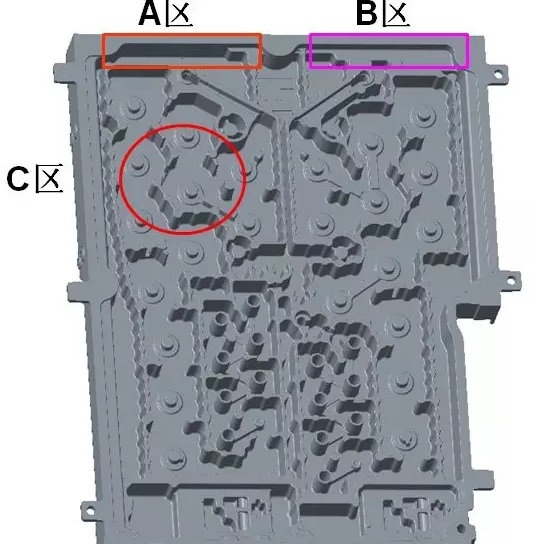

From the analysis of the product structure (see Figure 4), the area A on the left is the space between the inner cavity structure and the wall of the water tail. The aluminum liquid is filled to this position and hits the mold wall to form a wrap, which affects the filling and exhaust of the aluminum material. , When the exhaust is not smooth, high pressure will occur, which will cause difficulty in melt filling and insufficient injection volume, resulting in the defects of loose structure and exposed pores in the C zone of the casting. And the transition position between the A zone and the A zone and the C zone, because it is relatively close to the tail, the overflow system can discharge part of the gas, so there is no pore defect in the actual production. The structure of zone B on the right is connected to the wall of the water tail, which can be filled and exhausted smoothly, so there is no pore defect in the production. In addition, the die-casting engineers at the trial production site are already conducting trial production under good process conditions, and there are no pore defects in the product due to die-casting process problems, such as excessive air content in the aluminum liquid, excessive spraying, unreasonable injection process parameters, etc. .

Figure 4 Product structure analysis

3.2 CAE simulation analysis

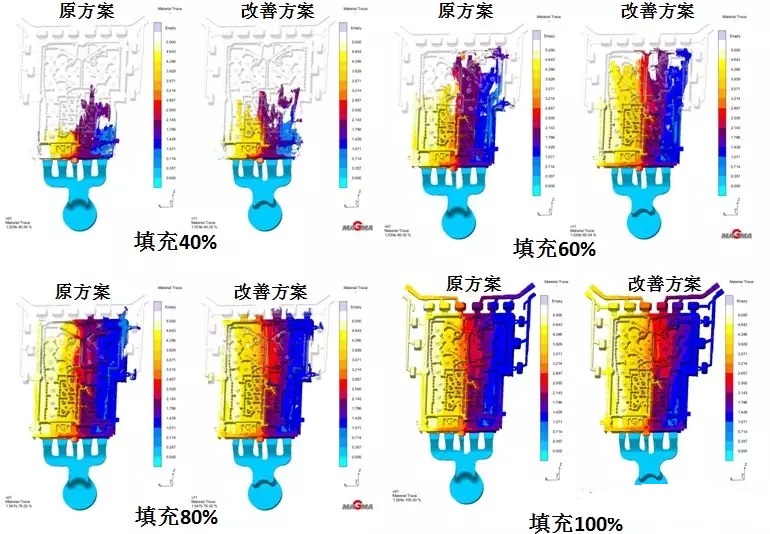

Use the MAGMA simulation software to simulate the die-casting scheme. From the filling 40%, 60%, 80%, 100% in Figure 5, it is found that the filling of the left half of the product is slower than the right half; and the filling speed of gate 1 is slower than gate 2. The filling speed is fast, and an entrained area appears in the upper left corner of the product.

Figure 5 CAE analysis of product filling

Figure 5 CAE analysis of product filling

4. Defect improvement

4.1 Measures to resolve defects

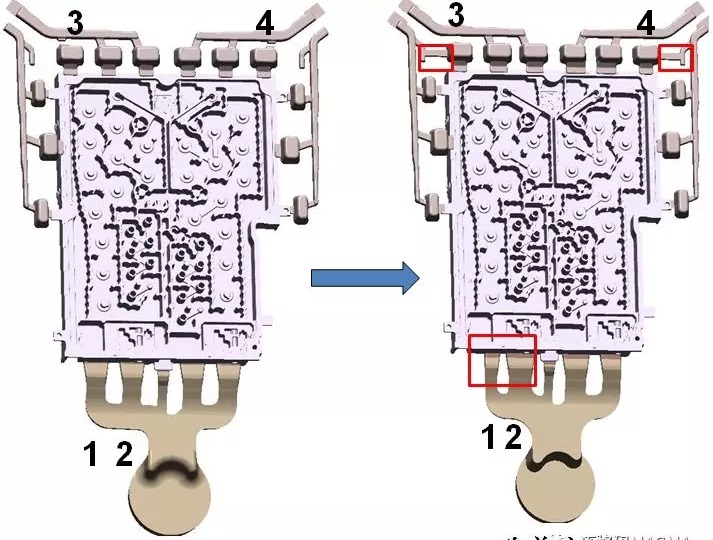

From the MAGMA simulation, the filling speed of sprue 1 is too fast, and the filling speed of sprue 2 is too slow, causing the leftmost aluminum material of the product to quickly seal the slag bag opening at the tail, causing poor exhaust and forming an air-entrained area. In addition, the filling of the left half of the product is slower than the right half. The improvement plan we propose is to reduce the filling speed of sprue 1 by half-sealing, and increase the width of sprue 2 to the left by 5mm to speed up the filling speed, so that the filling of the left and right sides of the product tends to be balanced. In addition, in order to improve the exhaust, slag bags 3 and 4 open exhaust channels to allow the gas on the left and right corners of the product to be directly exhausted to the exhaust plate of the mold (see Figure 6).

Figure 6 Scheme improvement diagram

4.2 CAE analysis of the improvement plan

We put the improvement plan in the MAGMA software for CAE simulation. By analyzing the simulation results of 40%, 60%, 80%, and 100% filled by the original plan and the improvement plan, it can be determined: After modifying the runner, the left half of the product The filling speed is faster than before, and the left half and right half of the filling tends to be balanced, and the filling of gate 1 is slower than the filling of gate 2, and no air-entrained area is formed in the upper left corner of the product.

Figure 7: Comparison of CAE analysis between the original plan and the improved plan

Figure 7: Comparison of CAE analysis between the original plan and the improved plan

4.3 Verification of the improvement effect

After on-site production trial production, the internal quality of the X-ray is shown in Figure 8. There are no pores in the defect position. The scrap rate at this location due to pores has been changed from 27.8% to 0%. Through mass production, sample delivery and user testing, the quality of the product meets the technical requirements, and the project successfully passed the verification and mass production.

This case is a model of the combination of on-site die-casting process technology and CAE technology to solve the problem of pore defects, shortening the development cycle of new products, and greatly improving economic benefits.

Figure 8 X-ray image of trial production after modification

Figure 8 X-ray image of trial production after modification

5 Conclusion

Aiming at the research on solving the pore defects of a communication part filter, the CAE simulation calculation is performed using MAGMA software to analyze the causes of pores in the aluminum alloy die-casting production process, providing a reference basis for the design of the mold gating system and the overflow system, and improving The quality of the castings, cost saving, shortening the development cycle, and improving economic efficiency have certain help.

Since there are many factors that affect the production of pores in aluminum alloy die-casting parts, which involve all aspects of the die-casting process, the problems that should be paid attention to in actual production are not limited to the improvement of the above-mentioned gating system and the design of the overflow system.