Die Casting Basic Principle

Since the 1920s, many people have done more in-depth research on the principle of die casting, and a series of relevant theoretical systems on the flow characteristics of liquid metal named by the proposer himself have emerged. These theoretical systems are mainly Barton’s theory and Brandt’s theory.

In the process of die casting, metal filling is an extremely complex comprehensive process including mechanics, hydrodynamics, thermodynamics and so on. It is closely related to the structure of dense parts, injection speed, pressure, pressure transfer mold temperature, liquid metal temperature, liquid metal viscosity, shape and size of gating system, etc.

When the superalloy hydraulic man is in the pouring system of the pressure transfer mold with lower temperature, various forms of heat exchange will occur between the liquid metal and the mold The molten metal loses heat, the temperature decreases, the mold gets coke and the temperature increases. When the temperature of molten metal decreases, the surface tension increases, the viscosity increases and the fluidity decreases. When they exceed a certain limit, the casting will produce casting defects such as unclear wheel seat, lack of meat, cold shut, crack, liquid inclusion and so on. In addition, when liquid metal fills the cavity, it is also affected by various resistances, such as gas resistance in the cavity, resistance when touching the mold wall and core

Therefore, the filling form of liquid metal plays a decisive role in the quality of die castings. Therefore, it is necessary to master the law of liquid metal filling form and understand the filling characteristics, so as to correctly design the gating system and obtain high-quality castings.

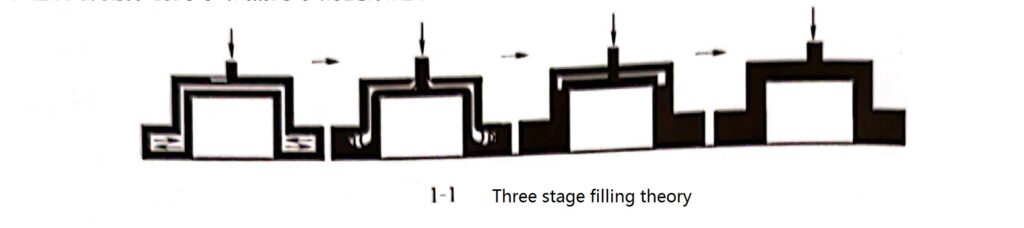

The principle of die casting is mainly based on HK Barton theory ♦ According to the theory, the process of filling zinc mold with liquid metal is a complex process including hydrodynamics and thermodynamics. The filling process can be divided into three stages, as shown in Figure 11-1 below

The first stage: the liquid metal enters the mold cavity in a shape close to the section of the inner gate, first strikes the opposite mold wall, expands around the mold wall and then returns to the gate, and gradually forms a shell (thin shell) on the mold wall through which the liquid metal flows.

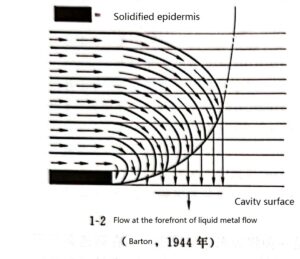

The second stage: the incoming metal is deposited on the surface of the thin shell for filling. The accumulation of disturbed metals expands and merges around the core formed in the first stage. Here, the rapidly flowing metal upper layer extends to the leading edge and rotates around the instantaneous rotation center in the liquid flow. When the metal flow stops, it has a considerable force to impact the cavity surface, and the rotation center is in this layer. Its inherent movement is consistent with the average velocity in the liquid flow. The metal in this layer has the minimum component of movement perpendicular to the liquid flow direction. Rotating around this center, the metal is gradually brought from the upper layer to the lower layer, so the skin thickness of the liquid flow is generally maintained until it is filled.

As shown in Figure 1-2, the skin initially formed at the first stage is at or near the solid line at the second stage.

The third stage: after the metal liquid is completely filled with the dense lining, the mold cavity, gating system and pressure chamber are a closed hydraulic system. In this system, the pressure is equal everywhere, and the injection force is in the continuous action of liquid metal through the center of the casting.