Precision and Efficiency: CNC Machining Manufacturer in China

What is CNC Machining ?

“CNC machining is a subtractive manufacturing technique used to produce parts by selectively removing material from a workpiece using cutting tools or other methods. To understand CNC machining, it is essential to first grasp the concept of CNC.

CNC stands for Computer Numerical Control, which involves the automated control of machine tools and parts through computer programming. The computer is instructed using machine-readable code called G-code (Geometric code), which is generated by specialized Computer-Aided Manufacturing (CAM) software based on digital 3D models of the components. Essentially, CAM software transforms a digital model into G-code, which then directs the computer to govern the speed, direction, and movement of the machine’s components during the manufacturing process.

The concept of machining, along with the associated equipment, predates the advent of CNC technology. In traditional machining, operators manually guide the movements of machine components. Depending on the specific operation and equipment, the operator may manipulate a rotating cutting tool against a stationary workpiece or vice versa, referencing a blueprint of the intended end product. This manual process is slow, prone to errors, limited in capabilities, and requires highly skilled operators for accurate execution.

By incorporating CNC technology, precision computer control is introduced to manage the movement, speed, and orientation of the workpiece, cutting tools, and other machine components. The integration of CNC transforms machining into a rapid, precise, and efficient manufacturing process.

How does CNC machining work? Types of CNC machining operations

CNC machining stands out as a remarkably versatile manufacturing process that excels in producing intricate and diverse geometries with precision. Its adaptability extends to a wide array of materials, including metals, plastics, glass, ceramics, foam, paper, wood, and more. By offering compatibility with such a broad range of materials, CNC machining has revolutionized manufacturing capabilities, fostering innovation and streamlining efficient production processes.

At the core of CNC machining is a sophisticated system that operates through various operations and technologies. These operations are defined by the type of machine used, the geometries and features produced, material removal methods, and cutting technologies employed.

The primary types of CNC machining operations include:

- CNC milling

- CNC turning

- CNC drilling

- CNC routing

- CNC cutting

- Electronic Discharge Machining (EDM)

These operations are carried out by specialized machines equipped with specific cutting tools or mediums. Together, they elevate CNC machining to a level of versatility and proficiency that is crucial for modern manufacturing processes. The production of a component may involve any combination of these CNC machining operations.

Among these operations, CNC milling and CNC turning stand out as the most prevalent and widely utilized forms of CNC machining, encompassing the majority of CNC machining applications. Other CNC machining operations often represent variations or extensions of these foundational techniques.

CNC milling

CNC milling stands out as one of the most favored CNC machining methods. It employs a rotating cutting apparatus to precisely eliminate sections of a material block. In this procedure, a motorized spindle propels the cutting tool into a workpiece secured on a worktable below it. Throughout milling, the cutting tool and workpiece adjust position in relation to each other across diverse axes, enabling the cutting tool to reach various sections of the workpiece. These movements are governed by a microprocessor integrated within the machine and carried out via mechanical feed systems. CNC milling devices or CNC mills are responsible for executing this process.

CNC milling has the capability to generate a diverse range of intricate shapes and features, encompassing cubic and parametric geometries, as well as curves and contours. This CNC machining process achieves such versatility through a range of cutting methods known as milling operations, such as face milling, plane milling, angular milling, and form milling. These operations differ based on the shape and positioning of the cutting tool, as well as the type of cuts they create. Typically cylindrical in shape, milling cutting tools are equipped with teeth at either their tips or around their entire perimeters.

Moreover, CNC milling can handle drilling and routing tasks, although there exist specialized machines dedicated to these specific processes. These machines exhibit certain variations tailored to optimize performance for particular applications.

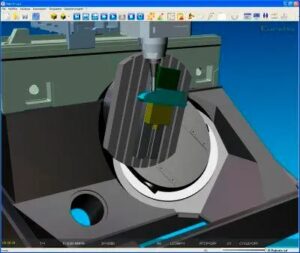

3-axis CNC milling

In 3-axis CNC milling, either the cutting tool or the workpiece has the capability to maneuver in three lateral directions: along the X (side-to-side), Y (forward and backward), and Z (up and down) axes. The illustration below depicts a CNC machine equipped for 3-axis milling operations.

5-axis CNC milling

5-axis CNC milling is an advanced machining process that involves the simultaneous movement of the cutting tool or the workpiece along five different axes: X, Y, Z, and two additional rotational axes. This capability allows for the production of complex and highly intricate parts and components with a high degree of precision and accuracy. 5-axis CNC milling machines are commonly used in industries such as aerospace, automotive, and medical manufacturing, where intricate geometries and tight tolerances are required.

CNC Turning

In CNC turning, the workpiece is placed on a rotating spindle while a stationary cutting tool is brought to it. The process commences with a block of material securely clamped in position by a chuck at one end. Depending on the workpiece’s size, additional support from a tailstock may be required at the opposite end.

Upon machine activation, the chuck spins the workpiece at high speeds, and the cutting tool advances into it at specified depths, shaping the desired form. Typically, the cutting tools used in turning are flat and cubic with sharp tips.

CNC turning is primarily employed to produce cylindrical, conical, and hexagonal shapes and features. This machining operation achieves its purpose through various cutting techniques dependent on the shape and orientation of the tool. Common CNC turning operations include straight cutting, taper cutting, facing, and grooving. Although turning is faster and less complex than milling, it is constrained in the range of geometries it can fabricate.

The machines responsible for CNC turning are referred to as CNC lathe machines or CNC turning machines. Additionally, there are advanced turning centers that integrate both turning and milling capabilities.

CNC drilling

CNC drilling involves the precision process of creating vertical holes in a workpiece by using a rotating cutting tool or drill bit under the control of a CNC system. This technology ensures accurate and precise drilling by regulating factors like drill speed, depth, hole position, and more.

Dedicated CNC drilling machines, although able to perform hole-drilling tasks also carried out by CNC milling and turning machines, are optimized for specific drilling applications. These machines typically feature a large build platform and a gantry x-y motion system suitable for accommodating sizable, flat workpieces. The cutting tools used are specialized drill bits designed for drilling operations. Some advanced CNC drilling machines may include turret-type drill heads capable of holding multiple drill bits and cutting tools for seamless mid-operation tool changes without machine stoppages.

Compared to CNC milling machines, drilling operations with CNC drilling machines are generally less complex and less expensive. Common tasks performed include drilling, tapping, threading, and boring.

CNC routing

CNC routing is a surface machining process where sections of a workpiece’s surface are precisely removed to replicate a specific pattern, shape, or detail. During this operation, a rotating cutting tool lightly penetrates the workpiece’s surface. While CNC milling machines can also perform routing tasks, there are specialized, simpler CNC routers designed specifically for this purpose.

Dedicated CNC routers prioritize speed and smooth movements over torque since routing is primarily a surface-level operation. As a result, these machines are commonly used for softer materials like wood and aluminum due to their efficiency in such applications.

CNC Design Considerations for Optimal Performance

When it comes to CNC machining, precision is the name of the game. While CNC technology offers exceptional accuracy, achieving absolute perfection in part production remains a challenge. Understanding tolerances is key to ensuring that your CNC designs meet functional requirements while accounting for manufacturing limitations.

Tolerance plays a crucial role in CNC machining, defining the acceptable deviation from the intended dimensions that still allows the part to function as intended. Different projects have varying tolerance requirements, but certain industry-standard tolerances apply across CNC machining operations:

– 3-axis milling: ± 0.13 mm (0.005″)

– 5-axis milling: ± 0.13 mm (0.005″)

– Lathe: ± 0.13 mm (0.005″)

– Router: ± 0.13 mm (0.005″)

– Engraving: ± 0.13 mm (0.005″)

– Screw Machining: ± 0.13 mm (0.005″)

– Steel Rule Die Cutting: ± 0.381 mm (0.015″)

– Surface Finish: 125RA

Considerations for Geometries and Features

To optimize your CNC designs, it’s vital to understand the limitations of the machines. Here are some key considerations for designing geometries and features for CNC machining:

1. Design internal edges with radii to accommodate the cutting tools’ cylindrical nature.

2. Avoid excessively deep cavities that can damage tools and hinder chip evacuation.

3. Opt for wall thicknesses that balance structural integrity and machining feasibility.

4. Use standard hole sizes and depths to streamline the machining process.

5. Limit thread length to ensure optimal holding force without unnecessary complexity.

Software Solutions for CNC Machining Success

The success of CNC machining heavily relies on specialised software that translates design concepts into actionable machine instructions. The three main types of software crucial for CNC machining are:

– CAD (Computer-Aided Design)

– CAM (Computer-Aided Manufacturing)

– CAE (Computer-Aided Engineering)

These software categories work together to streamline the CNC design and production process, enhancing accuracy and efficiency. By leveraging the capabilities of CAD, CAM, and CAE software, manufacturers can unlock the full potential of CNC machining technology.

For a comprehensive guide on CNC design best practices and software integration, explore our CNC design guide and unleash the power of precision engineering in your projects.

Precision CNC Machining Services in China

Introduction

As a leading CNC machining manufacturer in China, we specialize in high-precision machining services for industries worldwide. Located in Ningbo, China, our facility is equipped with state-of-the-art CNC machines, allowing us to deliver tight-tolerance, high-quality machined parts with exceptional accuracy and efficiency.

Whether you need CNC Turning, milling, 4-axis, or 5-axis machining, we provide end-to-end manufacturing solutions—from prototyping to mass production. Our expertise spans automotive, aerospace, medical, telecommunications, and industrial equipment, ensuring that every component meets the highest industry standards.

Our CNC Machining Capabilities

1. Advanced Machining Services

We offer a full range of CNC machining solutions, including:

- CNC Turning – Precision cylindrical parts with smooth finishes

- CNC Milling – Complex 3D geometries and intricate designs

- 4-Axis & 5-Axis Machining – Multi-angle precision for advanced components

- Swiss Machining – Ultra-precision for small, complex parts

2. Material Expertise

We machine a wide variety of materials, including:

✔ Metals: Aluminum, Brass, Copper, Carbon Steel, Stainless Steel, Steel Alloys

✔ Plastics & Engineering Polymers (upon request)

3. Surface Finishing Options

To enhance durability and aesthetics, we offer:

- Zinc Plating – Corrosion resistance

- Nickel & Chromate Plating – Wear resistance & conductivity

- Anodizing – Improved hardness & corrosion protection

- Custom Finishes – As per customer requirements

4. Tight Tolerance Machining

Our precision CNC machining ensures exceptional accuracy:

- ±0.003mm for shafts under 6mm

- ±0.005mm for larger diameters

- ±0.005mm linearity (under 100mm)

- ±0.01mm position tolerance

Why Choose Our CNC Machining Services?

✅ Unmatched Precision & Quality

With high-end CNC centers, lathes, and milling machines, we produce micron-level accuracy—critical for aerospace, medical devices, and high-performance automotive components.

✅ Fast Turnaround & Scalability

- Prototyping in 3-7 days

- Mass production with short lead times

- Flexible order quantities (low to high volume)

✅ Rigorous Quality Control

We use advanced inspection tools, including:

- CMM (Coordinate Measuring Machine)

- Micrometers & Thread Gauges

- Image Measuring Systems

- Roughness Testers

All parts undergo strict quality checks to ensure compliance with ISO, ASTM, and DIN standards.

✅ Cost-Effective Manufacturing

By leveraging China’s competitive supply chain, we provide high-quality CNC machining at competitive prices, reducing production costs without compromising quality.

✅ One-Stop Manufacturing Solutions

From CNC machining to finishing & assembly, we handle every stage—saving you time and simplifying logistics.

Industries We Serve

Our CNC machining expertise supports multiple industries, including:

🔹 Automotive & Aerospace

- Engine components, transmission parts, brackets

- Aircraft fittings, drone parts, satellite components

🔹 Medical & Dental Equipment

- Surgical instruments, implants, diagnostic devices

🔹 Electronics & Telecommunications

- Enclosures, heat sinks, connectors, RF components

🔹 Industrial Machinery & Automation

- Hydraulic systems, gears, robotic arms

🔹 Energy & Renewable Technology

- Solar panel mounts, wind turbine parts

How to Get Started with Us

- Send Your Design – We accept CAD, PDF, STEP, IGS, and JPEG formats.

- Get a Free Quote – Our engineers review your specs and provide pricing.

- Production & Inspection – Precision machining with full QC checks.

- Fast Delivery – Shipped globally with reliable logistics partners.

Conclusion – Your Reliable CNC Machining Partner in China

As a top-tier CNC machining manufacturer in China, we combine advanced technology, strict quality control, and cost-efficiency to deliver high-precision machined parts. Whether you need prototypes or large-scale production, we ensure exceptional quality, fast turnaround, and competitive pricing.

📩 Contact us today for a free quote! Let’s bring your designs to life with precision CNC machining solutions.