Mastering the Art of CNC Machine Programming: A Comprehensive Guide

Are you interested in learning how to program a CNC machine? If so, you’ve come to the right place! In this article, we’ll provide you with a comprehensive guide on how to program a CNC machine, step-by-step. Whether you’re a beginner or an experienced programmer, this guide will help you master the art of CNC machine programming.

Are you interested in learning how to program a CNC machine? If so, you’ve come to the right place! In this article, we’ll provide you with a comprehensive guide on how to program a CNC machine, step-by-step. Whether you’re a beginner or an experienced programmer, this guide will help you master the art of CNC machine programming.

Before we dive into the details, let’s first define what a CNC machine is. CNC stands for Computer Numerical Control, which means that the machine is controlled by a computer program. CNC machines are used in a variety of industries, including manufacturing, aerospace, and automotive, to name a few. They are capable of producing complex parts with high precision and accuracy, making them an essential tool for modern manufacturing.

Now, let’s get started with the programming process. The first step is to choose the right software for your CNC machine. There are many software options available, but some of the most popular ones include Mastercam, SolidWorks, and AutoCAD. Once you’ve chosen your software, you’ll need to create a 3D model of the part you want to produce. This can be done using CAD (Computer-Aided Design) software, which allows you to create a digital model of your part.

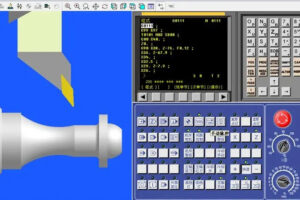

Once you have your 3D model, you’ll need to convert it into a format that your CNC machine can understand. This is done using CAM (Computer-Aided Manufacturing) software, which takes your 3D model and generates the toolpaths that the CNC machine will follow. The toolpaths are essentially a set of instructions that tell the machine where to move the cutting tool and how much material to remove.

Now that you have your toolpaths, it’s time to set up your CNC machine. This involves loading the program onto the machine and setting up the cutting tools. You’ll need to choose the right cutting tool for the job, as well as the appropriate cutting speed and feed rate. This will depend on the material you’re working with and the complexity of the part.

Once your machine is set up, it’s time to run the program. This involves pressing the start button and letting the machine do its work. It’s important to monitor the machine during the cutting process to ensure that everything is running smoothly. If there are any issues, you’ll need to stop the machine and make adjustments as necessary.

After the cutting process is complete, you’ll need to remove the part from the machine and inspect it for quality. This involves measuring the dimensions of the part and checking for any defects or imperfections. If everything looks good, you’re ready to move on to the next part.

In conclusion, programming a CNC machine may seem daunting at first, but with the right software and a bit of practice, anyone can master the art of CNC machine programming. By following the steps outlined in this guide, you’ll be well on your way to producing high-quality parts with precision and accuracy. So what are you waiting for? Start programming your CNC machine today!