Adjusting the eccentric shaft

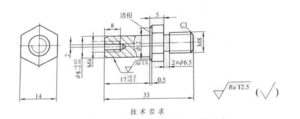

Figure 2-10 shows the structure, dimensions, and technical requirements for adjusting the eccentric shaft.

1. Analysis of part drawings

1) The eccentricity of the ∮8-0.03-0.06mm axis relative to the reference axis of the thread M8 is 2mm.

2) Tempering treatment 28-32HRC.

2. Adjust the machining process card of the eccentric shaft (see Table 2-134)

1. Tempering treatment 28-32HRC

2. Sharp corner rounding off

3. Material 45 steel

Figure 2-10 Adjusting the eccentric shaft

Table 2-134 Adjustment of eccentric shaft machining process card

| Operation No | Process name | Content of process | Process equipment |

| 1 | blanking | Hexagon steel 14mm × Mm (10 pieces connected) | saw machine |

| 2 | heat treatment | Conditioning treatment 28 -~32HRC | |

| 3 | Machining | Clamp one end of the hexagonal steel from the centering chuck, and the outer length of the chuck is 40mm. Turn end face, turn thread outer diameter ∮8-0.05-0.10mm and groove 2 ×∮6.5mm. 12mm length, chamfer C1, thread M8 Measure 15.5mm from the end face inwards, turn the hexagonal steel to make its excircle size be ∮12mm, and ensure that the total length is 34mm and cut off |

C620 Thread ring gauge |

| 4 | Machining | Use self-centering or four-jaw single-acting chuck to clamp special vehicle eccentric tooling. Locking and positioning with M8 thread and thread end face, turning the eccentric part ∮8-0.03-0.06mm ,turning the end face, ensuring the total length of 33mm and 17+0.1+0.3mm mm. Drilling M4 thread bottom hole 3, 3mm, depth of 12mm, tapping thread M4, depth of 8mm | C620, special eccentric tooling, M4 screw tap |

| 5 | Inspection | Check the dimensions of each part according to the drawing requirements | |

| 6 | Warehousing | Painting anti-rust oil, warehousing |

3.Process analysis

1) The structure of the eccentric shaft is simple to adjust, and the coarse follow-up value Ra of the outer surface is 1,6 μm. General accuracy requirements. M8 is a plain thread, mainly used for fine adjustment of the size adjustment mechanism.

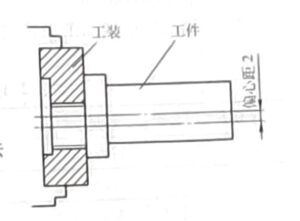

2) The key of parts processing is to ensure the eccentricity of 2m. Due to the small size of each part of the eccentric shaft, the eccentric machining can be completed by installing the eccentric fixture on the lathe (see Figure 2-11).

Figure 2-11 Machining with Eccentric Fixture

As specified in the process, take M8 thread and end face as the positioning reference for lathe eccentricity. Process an M8 thread hole with an eccentric distance of 2mm on the tooling, clamp the eccentric tooling on the self-centering or single-acting chuck of the lathe, align it according to its outer diameter and then clamp it.

3) If the eccentric shaft is processed and adjusted with bar stock (round steel), the processing method is basically the same as that of hexagonal steel, and only one milling hexagonal process is added.